BLOG

A New Quality Standard for Interior Doors with Makser Cold Press Machines

Why cold pressing matters in door production

Interior doors define both the look and the use of a space. The quality of pressing directly shapes flatness, bond strength and surface consistency—key to doors that stay true and look premium for years.

Makser Cold Press Machines: advantages at a glance

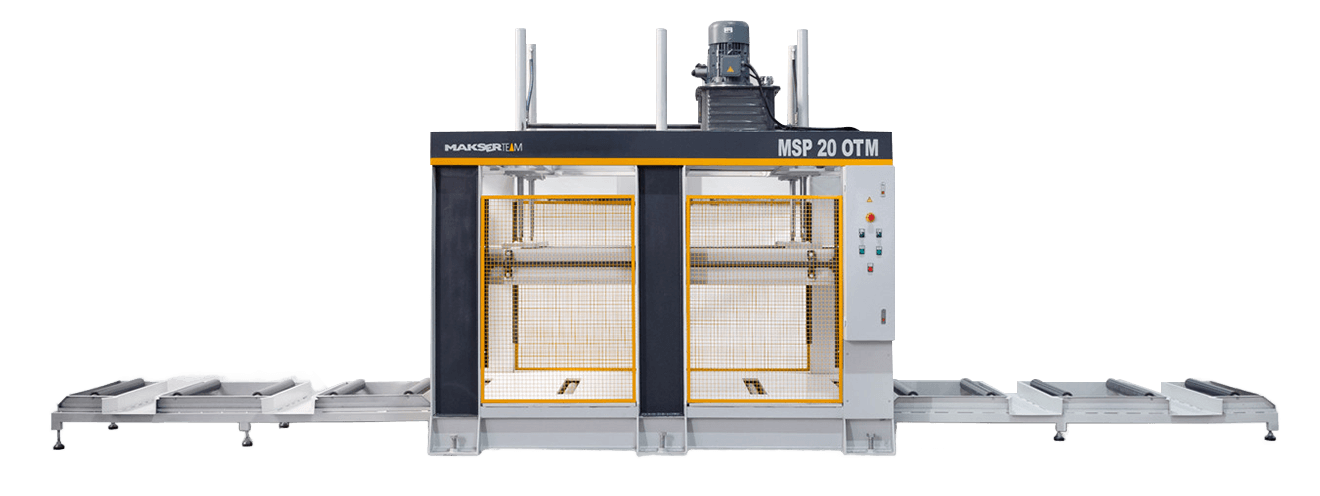

- High capacity: Press up to 20–30 doors per cycle (model-dependent) to accelerate throughput.

- Uniform pressure: Robust frame and hydraulic balance help deliver stable, distortion-free panels.

- Premium surfaces: Smooth, even faces ready for trimming, edge banding and final finishing.

- Process efficiency: Protect quality at scale while keeping unit costs predictable.

Cold Pres Msp 20 OTM

Technology that makes the difference

Makser cold pressing consolidates MDF/wood-based layers under even, repeatable pressure. The result:

- Reduced risk of warping, telegraphing or surface irregularities

- Homogeneous, elegant finishes that hold their look in daily use

- A dependable base for subsequent operations (machining, coating, assembly)

Tailored to your line

Every production line is unique—Makser adapts to it.

- Classic interior doors with standard sizes

- Modern designs with distinctive skins and layouts

- Project-specific formats that demand special sizes or materials

We provide configurable pressing solutions to match your parts, cycle time targets and upstream/downstream machines.

Where Makser fits in your flow

- Panel lay-up and adhesive application

- Cold pressing for structural stability

- Sizing/trim, edge banding and hardware preparation

- Final inspection, packing and shipment

Result: a higher standard—door after door

With Makser cold press machines for interior doors, manufacturers combine quality, efficiency and reliability. Each door leaves the line with strong structure, smooth surfaces and consistent aesthetics.

CTA: Elevate your door production with Makser Cold Press technology—request a demo or quotation today.