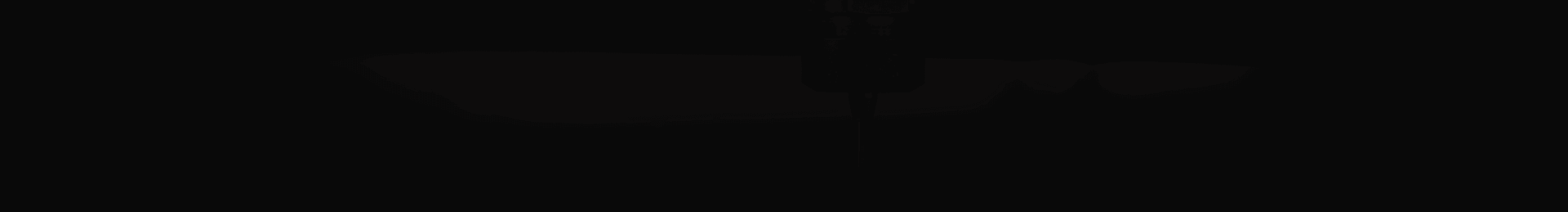

MSP 30 OTM Cold Press

Makser Cold Press Machines

Energy Saving

Consumes significantly less electricity compared to hot presses.

Natural Structure Preserved

Allows production without damaging the original structure of the material.

Minimal Risk of Thermal Degradation

Safe pressing at ambient temperature.

High Capacity

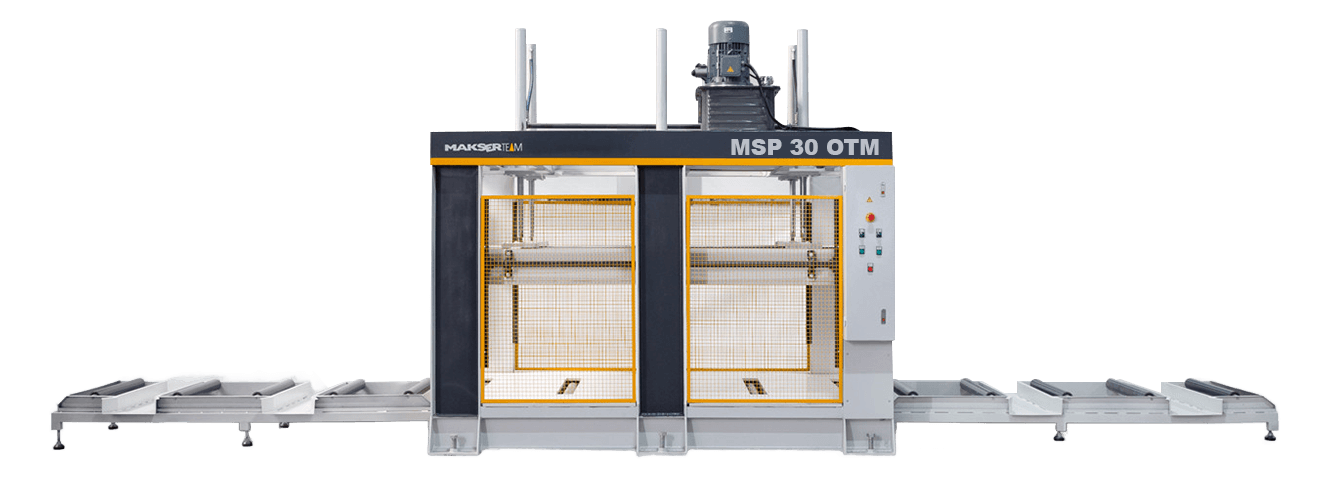

Enables pressing of up to 20–30 doors at the same time.

Long-Lasting Performance

Robust construction, high-quality materials and precise engineering.

Customer-Specific Solutions

Customization based on capacity, dimensions and technical requirements.

High Capacity and Superior Efficiency

Makser Cold Press machines are engineered to integrate seamlessly into modern production lines.

Press up to 20–30 doors in a single cycle.

Uniform pressure distribution for consistent quality on every panel.

Optimized speed and repeatability for continuous serial production.

Solutions Tailored to Your Needs

Every production facility is unique, and each Makser machine can be configured around your process.

Adaptation to your required production capacity.

Custom dimensions designed for your line and layout.

Technical options configured to your specific applications.

Strong in Durability, Reliable in Operation

Makser Cold Press machines are built for long-term, stable performance under demanding conditions.

Manufactured from carefully selected, high-quality materials.

Precision engineering ensures a long, trouble-free service life.

Operates reliably even in intensive, multi-shift production.

Our After-Sales Support and Services

MakserPress provides end-to-end support before, during and after machine installation.

Pre-sales consultancy to define the right configuration.

Professional installation and practical operator training.

Technical service and genuine spare parts supply.

Between Hot Press and Cold Press Key Differences

• Operates at ambient temperature, preserving the natural structure of the material.

• Reduces your energy bills and is more economical in the long term.

• Provides high efficiency with the right glue selection and pressure settings.

• Consumes far less electricity compared to hot presses.

Automatic Systems & Smart Support

Frequently Asked Questions (FAQ) – Makser Cold Press Machines

What are the differences between cold press and hot press machines?

Cold press machines operate at ambient temperature and preserve the natural structure of the material.

Compared to hot presses, they consume significantly less energy, eliminate the risk of thermal degradation and are more economical in the long term.

What is the capacity of Makser cold press machines?

Standard models can press up to 20–30 doors at the same time.

However, depending on customer requirements, we can offer special solutions from 10 doors up to 90 doors per cycle.

How is the energy consumption?

Cold press machines consume much less electricity than hot presses.

This provides significant savings on energy bills and offers an environmentally friendly production option.

What is the service life of the machine?

Makser cold press machines deliver long-term performance thanks to their robust frame, high-quality materials and precise engineering.

They can be used safely even under intensive production conditions.

Which materials can be pressed with cold press machines?

These machines provide reliable pressing for a wide range of materials such as door panels, MDF, chipboard and veneer panels.

Can Makser cold press machines be customized?

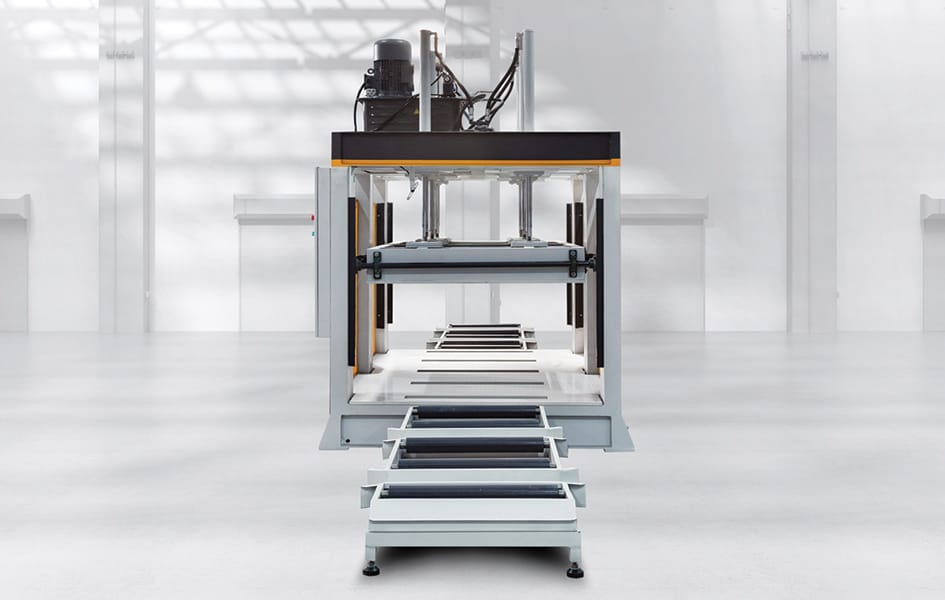

Yes. Working area dimensions, number of cylinders, pressing force and capacity can be customized according to your project, product types and production layout.

How is adhesive bonding quality ensured?

With the correct adhesive selection and uniform pressure distribution, homogeneous bonding is achieved across the entire surface. This delivers high quality in terms of both durability and appearance.

Do you provide after-sales support?

Yes. Makser provides pre-sales consultancy, professional installation, operator training, technical service and genuine spare parts support.

Are the working dimensions fixed, or can they be adapted to customer projects?

The working dimensions of Makser cold press machines can be specially designed and manufactured according to the customer’s project.

This allows us to offer solutions that fit perfectly into each production line.

What is the warranty period?

The MSP 30 OTM Cold Press is a configurable system. Working area dimensions, number of cylinders and pressing force can be adjusted on a project basis according to your production line and door/panel requirements.

Technical Specifications

| Feature | Value |

|---|---|

| Press Table | 1300 × 2500 mm |

| Distance Between Plates | 850 mm |

| Press Cylinders: | 6 pcs · Diameter: 70 mm · Stroke: 750 mm |

| Pressing Force | 18 tons |

| Machine Capacity | 1–30 Doors |

| Loading Type | Roller loading unit + double conveyor |