Thermoform

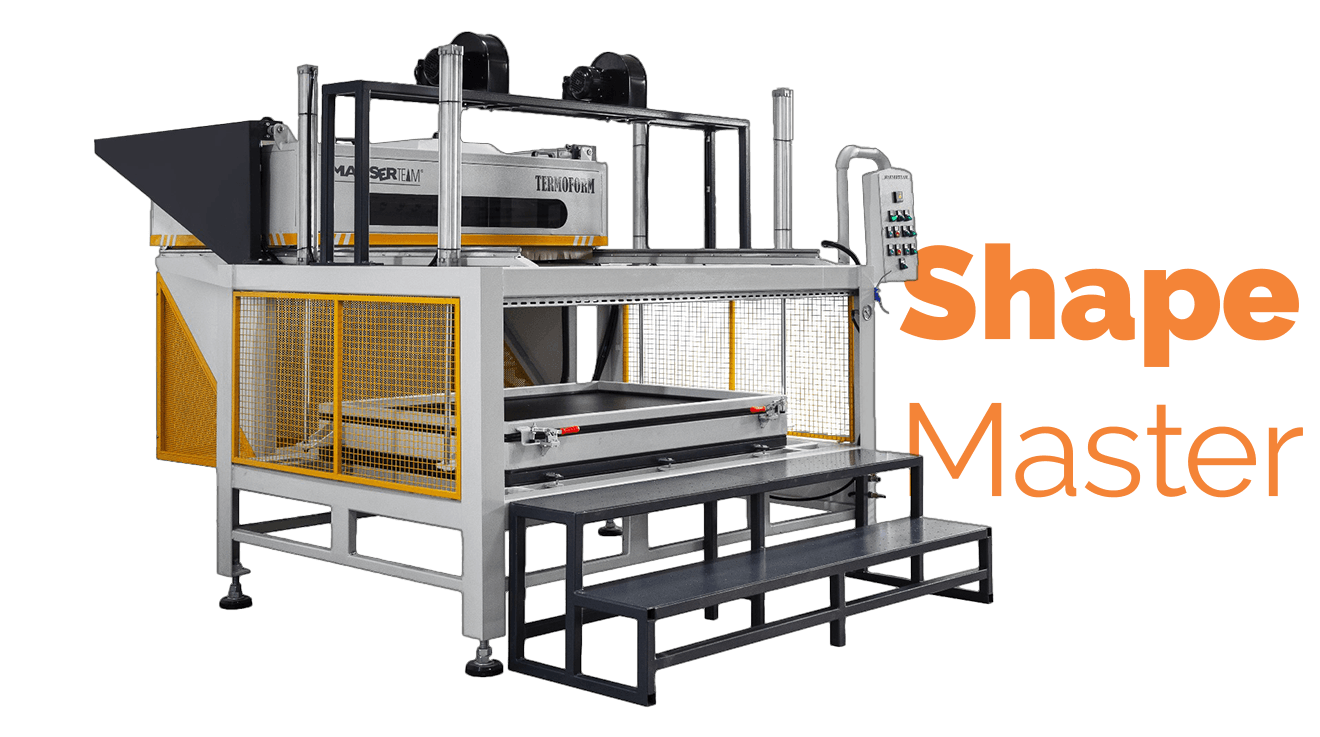

ThermoForm Shape Master

High Performance with Precision Forming

Shape Master forms ABS and similar materials quickly and precisely, using positive and negative vacuum to capture every mold detail and deliver smooth, consistent surfaces.

Innovative Technology, Unlimited Design Freedom

Working with a wide range of molds and product designs, Thermoform Shape Master gives engineers freedom to refine ideas rapidly and turn new concepts into production-ready parts.

A Real Transformation in Production Processes

Equipped with advanced thermoforming technology, Shape Master streamlines workflows, shortens setup times and helps manufacturers achieve reliable, repeatable quality in every cycle.

Diverse Application Areas

ThermoForm Shape Master - What Can Be Produced?

Packaging Materials

Thermoforming machines are used to produce plastic trays, blister packs, clamshell packaging and other packaging solutions. They provide durable and hygienic packaging used in a wide range of sectors, from the food industry to medical devices.

Automotive Parts

In the automotive sector, many components such as interior trim parts, console panels, door panels and other interior parts are produced using thermoforming machines. These parts are generally made from plastic materials and are designed to meet specific strength and design requirements.

Medical Device Components

Many medical devices include special parts produced with thermoforming machines. These include surgical trays, medical blister packs, respiratory device components and more. Special materials can be used to meet sterilization and hygiene requirements.

Electronic Components

The electronics industry relies on many parts produced with thermoforming machines. Plastic housings, board carriers, mounting trays and other components are used in the assembly of electronic devices and are designed to meet insulation, durability and other specific requirements.

Construction Materials

Some thermoplastic materials are used in various applications in the construction sector. Thermoforming machines can be used to produce wall claddings, suspended ceiling panels, window surrounds and other structural parts. These components are generally lightweight, durable and easy to clean.

A Real Transformation in Production Processes

Equipped with thermoforming technology, Shape Master is not only a forming tool but also a solution partner that transforms your production processes. In a sector where you race against time, this machine offers efficiency, flexibility and quality at the same time.With its advanced forming capability, the thermoforming machine ensures repeatable quality in every cycle.

ThermoForm Panel

ThermoForm Table

ThermoForm Enclosed Table

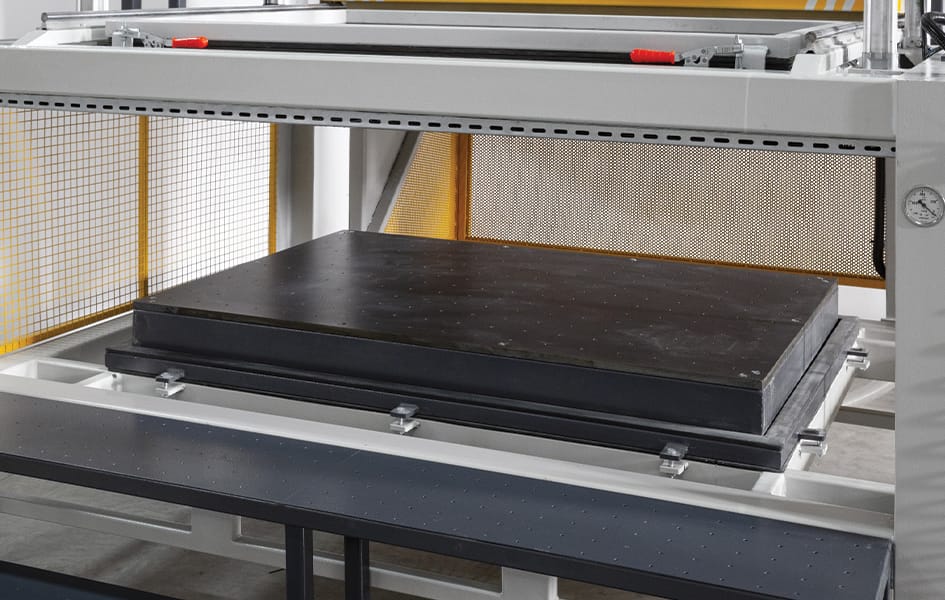

The ThermoForm Shape Master is not a fixed, one-size-fits-all machine, but a flexible system that can be configured according to your specific production needs. Key technical components such as the heating system (zoned heating, SSR-controlled modules), working dimensions, blowing unit, bottom heating and air support, as well as hydraulic or pneumatic lifting systems can be engineered based on the material, product geometry and required production capacity.

In addition, full automatic automation options allow integration into high-volume production lines, enabling repeatable, efficient mass production.

Therefore, the technical specifications listed below are core reference values and can be customized to meet your project-specific requirements.

Technical Specifications

| Feature | Value |

|---|---|

| Table | 1060 × 2300 / 1060 × 2300 / Custom sizes |

| Turbine Heating System | 190V · 600 W · 620 mm R |

| Vacuum System | 111 - 380 m³/hour |

| Temperature Sensor | Laser temperature sensor |

| PVC Loading Unit | Standard loading |

| Mold System | Custom-made (according to production function) |

| Fault Warning System | Buzzer |

| Operator Panel | 7" touchscreen |

| Electrical & Electronic | Schineider / Siemens |

| Drive Motor | 0.37 kW · 1/15 S40 |

| Drive Gear System | Mod 2 spur gear |

| Cycle Time | 1–4 mins |

| Weigh | 1650 kg |

| Machine Dimensions | W: 1310 · H: 1450 · L: 5500 (mm) |

| Cooling System | Turbo fan cooling system |

| Total Power Consumption | 34 kW |

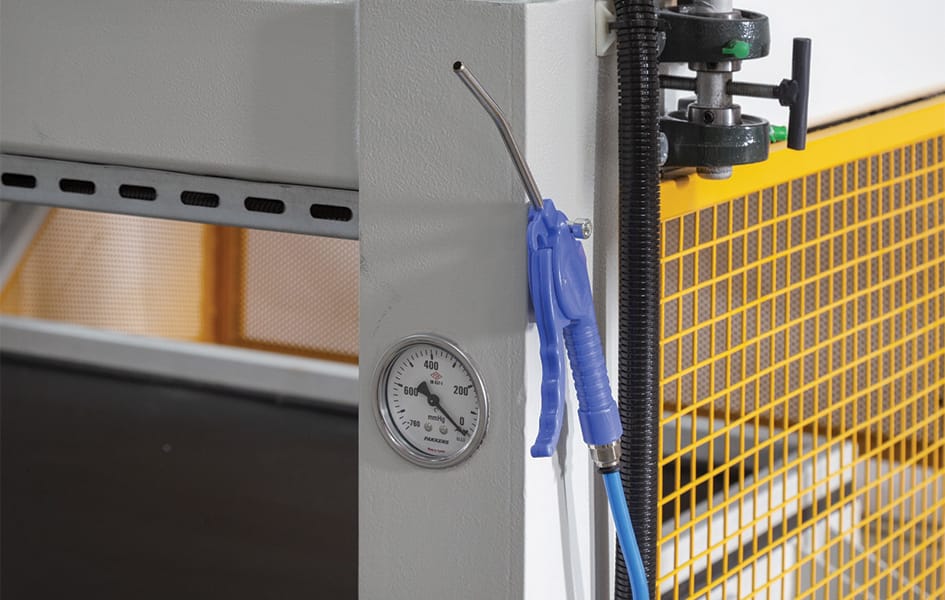

| Total Air Requirement | 8 bar |