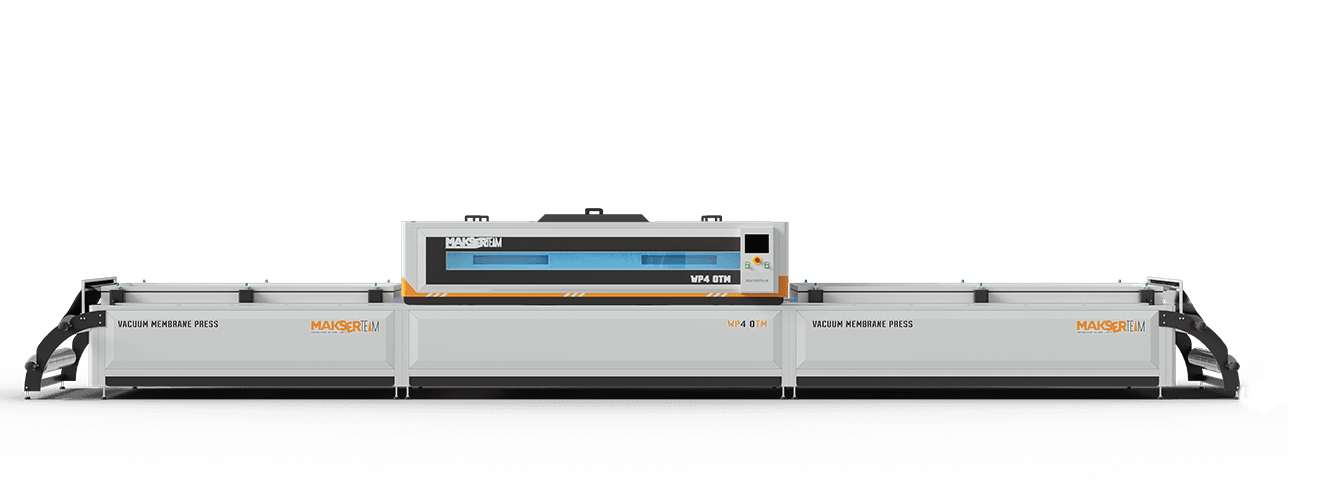

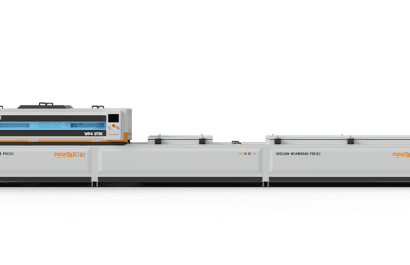

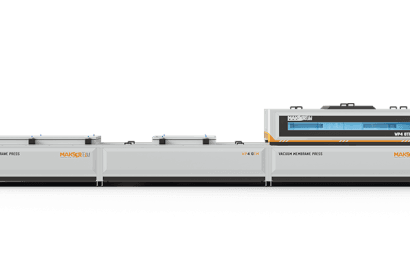

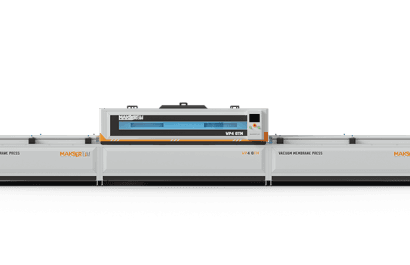

Vacuum Membrane Press WP4 OTM

Every Piece Of Furniture Tells A Story, Every Surface Is An Art

Vacuum Membrane Press WP4

Makser WP4 brings modern surface lamination technology into furniture and decoration production lines.On the surfaces of MDF, HDF, chipboard, HPL and similar panels (optionally including the edges), thermoformable materials such as PVC foil and PET/PETG are laminated perfectly using strong vacuum and controlled heat.In this way, from kitchen and bathroom cabinet doors to table tops, interior room doors, decorative panels and office furniture, you achieve homogeneous, durable and aesthetic results across a wide range of applications.

As an advanced vacuum press system, it delivers strong adhesion and stable lamination results on all complex surfaces.

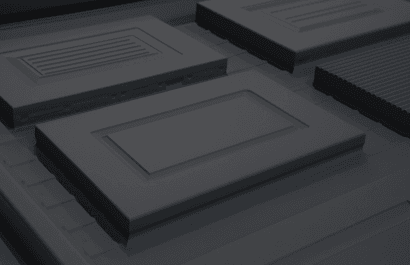

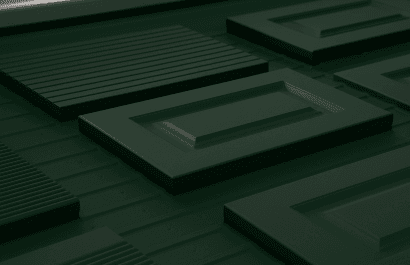

Take Your Door and Cabinet Door Production to the Next Level

Fast Production: Average cycle time of 1–3 minutes

High Quality Results: Homogeneous lamination, aesthetic appearance

Low Cost: Energy saving and reduced waste rate

Long Service Life: Robust frame structure and durable components

FEATURES THAT MAKE MAKSER MACHINES STAND OUT

In addition to being a powerful vacuum membrane press, the WP2 also performs as a reliable vacuum press for a wide range of materials.

FULL-LENGTH HEATING ELEMENTS

In many machines, segmented heaters create uneven surface temperature and weak spots.

👉 Makser full-length elements ensure uniform heat and consistently smooth, high-quality lamination.

ACTUATED VALVE

Actuated valves control vacuum and pressure fully automatically and with high precision.

👉 This brings faster cycles, stable process control and a significantly lower error rate.

WATER-COOLED VACUUM PUMPS

Water-cooled vacuum pumps combine strong suction performance with low maintenance needs.

👉 They support quiet, efficient and environmentally friendly production conditions.

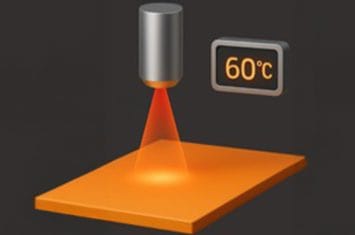

INFRARED TEMPERATURE CONTROL

Infrared sensors continuously measure the temperature directly on the panel surface.

👉 This keeps the process in the ideal window and delivers more consistent, defect-free results.

INTELLIGENT SUPPORT FOR VACUUM POWER: AIR TANK

The integrated air tank reduces the load on the vacuum motor during each cycle.

👉 Vacuum builds up faster and more evenly, lowering energy use and extending motor life.

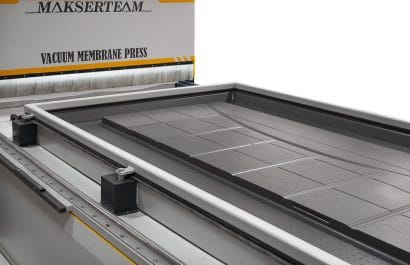

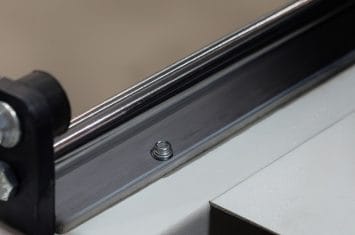

CHROME RAIL

Chrome rails offer higher wear resistance than conventional transmission rails.

👉 Smooth, low-friction motion protects positioning accuracy and ensures long-term stability.

USER-FRIENDLY AND EFFICIENT

An advanced control panel and intuitive interface make the machine easy to operate.

👉 Shorter training times, fewer operator errors and higher overall productivity.

THERMAL INSULATION CURTAIN

Special insulation curtains minimise heat loss in the working area of the machine.

👉 Stable process temperatures reduce energy consumption and support sustainable production.

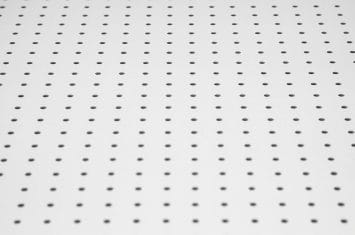

PERFORATED STEEL BASE

The robust steel base is designed to withstand high temperature and pressure loads.

👉 Its perforated structure distributes vacuum evenly, ensuring precise, repeatable lamination.

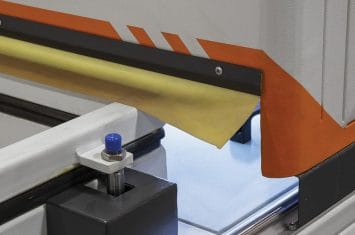

BEATING-MOUNTED PVC FOIL ROLL

Unlike conventional hanging systems, the bearing-mounted PVC foil roll holders used in Makser machines can be easily operated by a single person. 👉 Even large and heavy rolls can be pulled smoothly without requiring high force, making foil changeover fast and effortless.

SILICONE MEMBRANE TECHNOLOGY

The silicone membrane provides excellent results, especially in natural wood veneer applications.

👉 Even pressure across the entire surface prevents air pockets and waviness for a flawless finish.

SUPERIOR SURFACE PROTECTION WITH BAKED PAINT

Oven-baked paint protects the machine body against scratches, impacts and chemicals.

👉 The surface maintains its clean, premium appearance even after years of intensive use.

WHY MAKSERTEAM

CUSTOMER-ORIENTED APPROACH

Makser not only manufactures high-quality machines, but also sets customer satisfaction as a primary goal.

👉 It adds value to your production processes with need-based solutions and continuous support.

STRONG AFTER-SALES SUPPORT

Makser’s professional technical team provides fast solutions for any maintenance and repair requirements, either remotely or on site.

👉 A reliable service network to keep your production running without interruption.

SUPERIOR MATERIAL QUAILITY AND DURABILITY

MakserTeam Vacuum Membrane Press machines are built from high-quality materials with meticulous craftsmanship. They withstand years of intensive production and deliver maximum efficiency with minimal maintenance requirements.

GLOBAL SUCCESS

MakserTeam is a strong brand extending from Türkiye to the world, providing after-sales support, spare parts and consultancy services on a global scale.

YOUR BEST PARTNER IN FURNITURE PRODUCTION

With MakserTeam Vacuum Membrane Press machines, you combine quality, speed and aesthetics in furniture production – from kitchen cabinet doors to decorative panels – adding real value to your products.

UNLIMITED SPARE PARTS SUPPORT

MakserTeam supplies fast and reliable spare parts for all its machines.

This keeps your production running without interruption and extends the service life of your machine.

Frequently Asked Questions (FAQ) – Makser Vacuum Membrane Press Machines

What is a vacuum membrane press and where is it used?

Vacuum membrane press machines apply PVC foil or natural wood veneer onto MDF, HDF, chipboard and similar panels using heat and vacuum pressure. They are used to produce aesthetic, durable and long-lasting surfaces on kitchen cabinet doors, interior room doors, bathroom cabinets and decorative panels in furniture manufacturing.

What are the advantages of PVC foil lamination?

PVC foil lamination gives furniture a scratch-resistant and moisture-resistant surface with a long service life. Its wide range of colours and patterns offers great flexibility in interior design. It is an economical, environmentally friendly and visually appealing solution, which is why it is one of the most preferred methods in modern furniture production.

Why are chrome rails used in Makser machines?

Unlike conventional transmission rails that wear out over time, the chrome rail systems used in Makser machines provide high durability and a long service life. Their quiet, low-friction and smooth movement helps maintain precision over many years of operation.

What is the function of the actuated valve?

In the lamination process, actuated valves control the vacuum and pressure systems automatically and precisely. This provides higher production speed, increased quality and a lower error rate.

Why are water-based vacuum pumps preferred in Makser machines?

Environmentally friendly water-based (water-cooled) vacuum pumps offer high performance with low maintenance costs. They support quiet, efficient and eco-friendly production processes.

What is the advantage of baked-paint (oven) coating on the machine?

Professional oven-baked paint protects the machines against scratches, impacts and chemicals. As a result, the machines retain their clean and aesthetic appearance for many years.

What advantages does silicone membrane technology provide?

Silicone membrane delivers outstanding performance especially in natural wood veneer applications. By applying uniform pressure across the entire surface with vacuum, it prevents air pockets and waviness, ensuring a smooth and flawless lamination quality.

How do Makser machines benefit furniture production?

From kitchen cabinet doors to decorative panels, Makser vacuum membrane press machines combine quality, speed and aesthetics in furniture production, adding real value to your products.

What are the benefits of the user-friendly design?

Thanks to the advanced control panel and intuitive interface, the machine is easy for any operator to use. This means shorter training times, fewer operator errors and higher overall productivity.

What is the function of the air tank in Makser machines?

The air tank reduces the load on the vacuum motor and allows the vacuum to build up faster and more evenly. This means lower energy consumption, longer motor life and uninterrupted production.

What are the advantages of using full-length heating elements?

The full-length heating elements used in Makser machines provide uniform heat distribution across the entire surface. This ensures higher quality, more consistent and error-free lamination.

Why is infrared temperature control important?

Infrared sensors measure the temperature on the panel surface in real time. This improves lamination quality, minimizes the risk of defects and helps produce aesthetic and durable products.

How does the thermal insulation curtain benefit production?

Special insulation curtains minimize energy loss. Heat stability is maintained, production efficiency increases and overall energy consumption is reduced.

What is the purpose of the perforated steel base?

The steel base is designed to withstand high temperature and pressure. Its perforated structure ensures homogeneous distribution of vacuum power, resulting in stable positioning, long service life and high-precision lamination.

What is Makser’s customer-oriented approach?

Makser not only manufactures high-quality machines, but also prioritises customer satisfaction as a core objective. It offers need-based solutions and continuous support that add value to your production processes.

How is after-sales support provided?

Makser’s professional technical team offers fast solutions for maintenance and repair needs, either remotely or on site. This keeps your production running without interruption.

What is Makser’s global presence?

MakserTeam is a strong brand extending from Türkiye to the global market. It provides after-sales support, spare parts and consultancy services on an international scale.

Is spare parts support available?

Yes. MakserTeam provides fast and reliable spare parts supply for all its machines. This ensures your production continues without disruption and extends the lifetime of your equipment.

What is the purpose of the bearing-mounted PVC foil roll holder?

Unlike conventional hanging systems, the bearing-mounted PVC foil holders used in Makser machines can be easily operated by a single person. Even large and heavy rolls can be pulled smoothly without high force, making foil changeover fast and effortless.

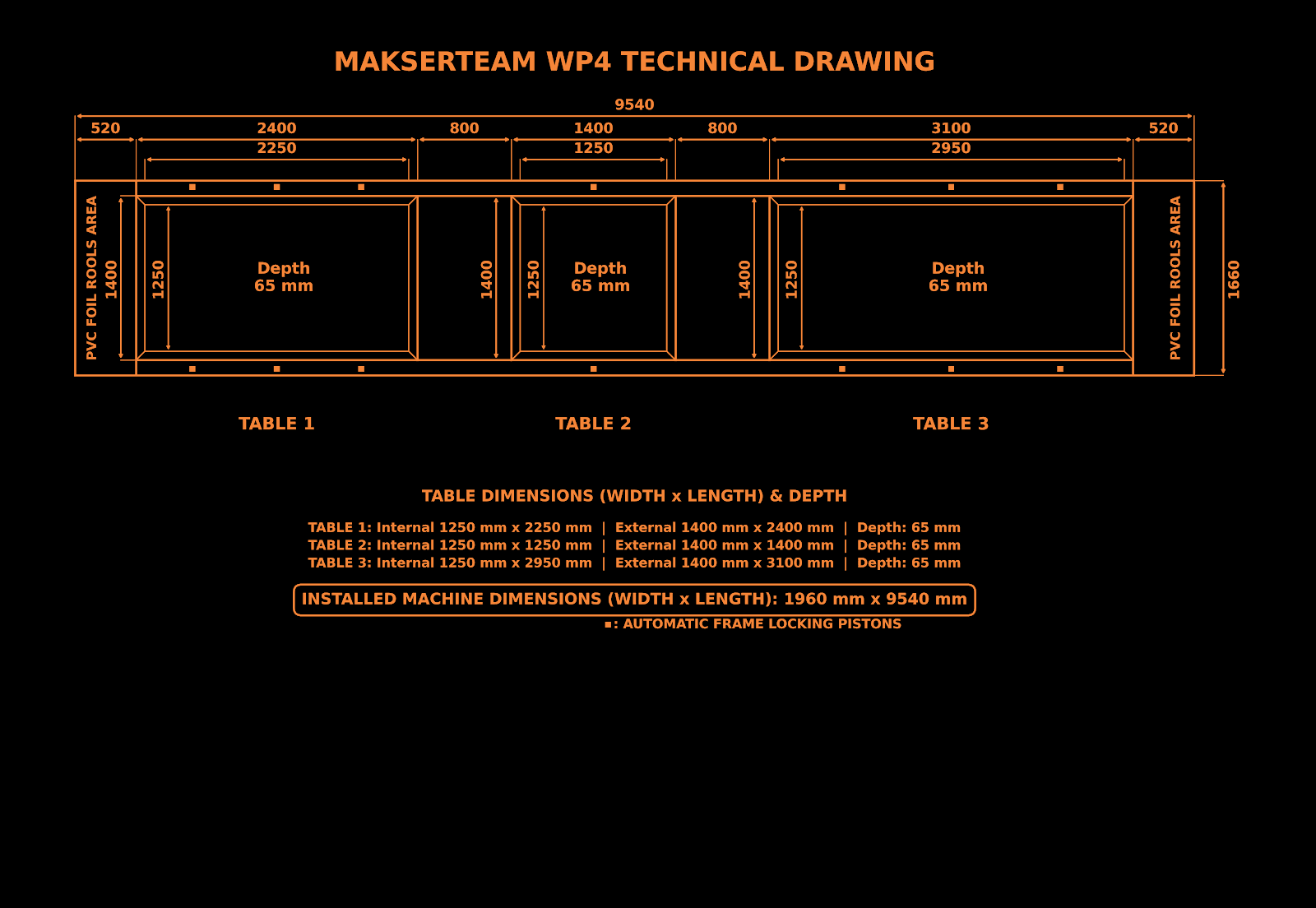

MACHINE DIMENSIONS AND TECHNICAL INFORMATION

Note: The size of the working table must be selected in line with the dimensions of the parts to be laminated; otherwise, material usage and layout efficiency will be negatively affected.

On request, custom sizes and additional technical drawings can be provided.

TECHNICAL SPECIFICATIONS

| Feature | Value |

|---|---|

| Production Table – Outer Dimensions | TABLE-1: 1400 mm × 2400 mm × 65 mm / TABLE-2: 1400 mm × 1200 mm / TABLE-3: 1400 mm × 3000 mm × 65 mm |

| Production Table – Inner Dimensions | TABLE-1: 1250 mm × 2250 mm × 65 mm / TABLE-2: 1250 mm × 1050 mm / TABLE-3: 1250 mm × 2850 mm × 65 mm |

| Turbine Heating System | Thermally insulated heating turbine 190V 800W (membrane required) or 190V 800W infrared heater |

| Vacuum System | 110 m³/hour oil vacuum pump or water-cooled vacuum pump |

| Temperature Measurement Sensor | Infrared thermometer capable of directly measuring the PVC foil or material surface |

| Total Air Consumption | 6 – 8 bar dry-type air |

| PVC Loading Unit | 4-roll capacity; bearing-supported roll holder on both sides of the machine |

| Mold System | Standard flat base or 24 mm square air-circulation mold |

| Error Warning System | In case of mispositioning, the user panel provides audible and visual warning |

| Controller | Delta 7 DOP 107 / PLC DVP 14 SS2 999 programmable control card |

| Electrical & Electronic Parts | Schneider automation / switchgear equipment and high-temperature-resistant cables |

| Motion Motor and Gearbox | 0.37 kW electric motor and 1/15 S40 worm gear reducer |

| Gear Motion System | Module 2 spur gear 8 and 25 tooth straight hub pinion gear |

| Operation Time | Melting time between 45 seconds – 5 minutes depending on the material thickness, physical properties and color |

| Weight | Standard machine weight is 1650 kg. May vary depending on project variations. |

| Machine Dimensions | W: 2000 mm · L: 7500 mm · H: 1500 mm (may vary depending on project variations) |

| Loading Dimensions |

Container type (Width × Length × Height): 1st piece 2000 × 3200 × 2500 mm Standard type (Width × Length × Height): 1st piece 2000 × 3200 × 1550 mm · 2nd piece 2000 × 3200 × 1100 mm |

| Total Energy Consumption | 34 kW/h — 1.69 per print |

| Turret Motion | 20 mm chrome lower support shaft and linear guide (operates silently for life) |

| Machine Intended Use | Kitchen cabinet doors, inner shelves, doors and similar applications |

| Machine Foot Assembly | Adjustable machine feet |

| Pneumatic Group | Clamping and gripping of PVC material from 0.20 mm up to 10 mm |

| Silicone Membrane Application | Membrane frame preferred for natural wood PP and interior covering |

| Single-piece Pressing | With separator application, optionally single-piece or lower-quantity door production can be performed |

| Cooling System | Fan cooling system providing 20% faster cooling in door surface production |

| Warranty Period | 1-year standard parts and labor warranty; 2-year technical support warranty (burning, breakage and transport damages are not included) |

| Our Certificates | CE Certificate, TSE-HYB Certificate, ISO 9001, Domestic Goods Certificate, Euro 1 Movement Certificate, Sabre Certificate, Cargo X Certificate |