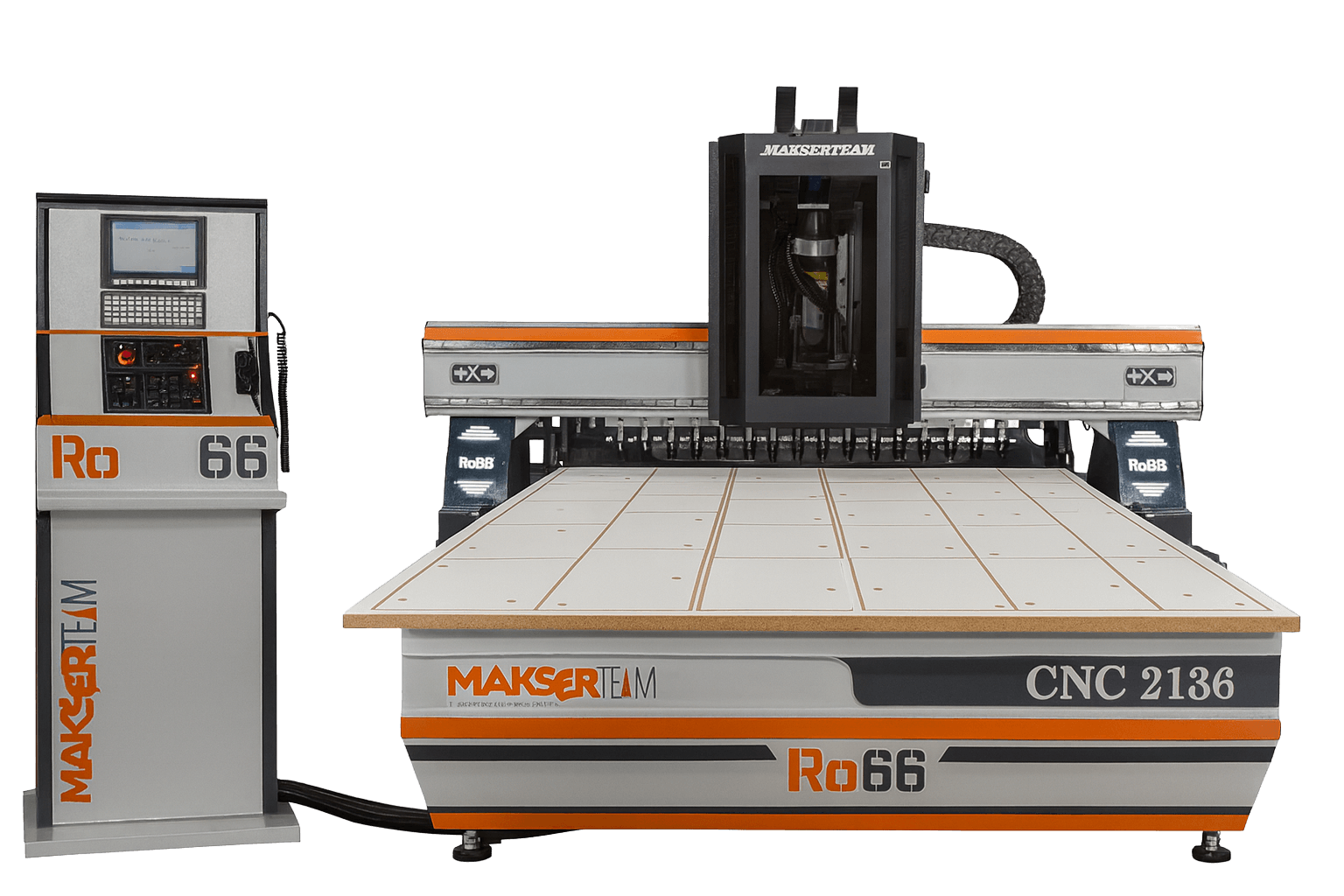

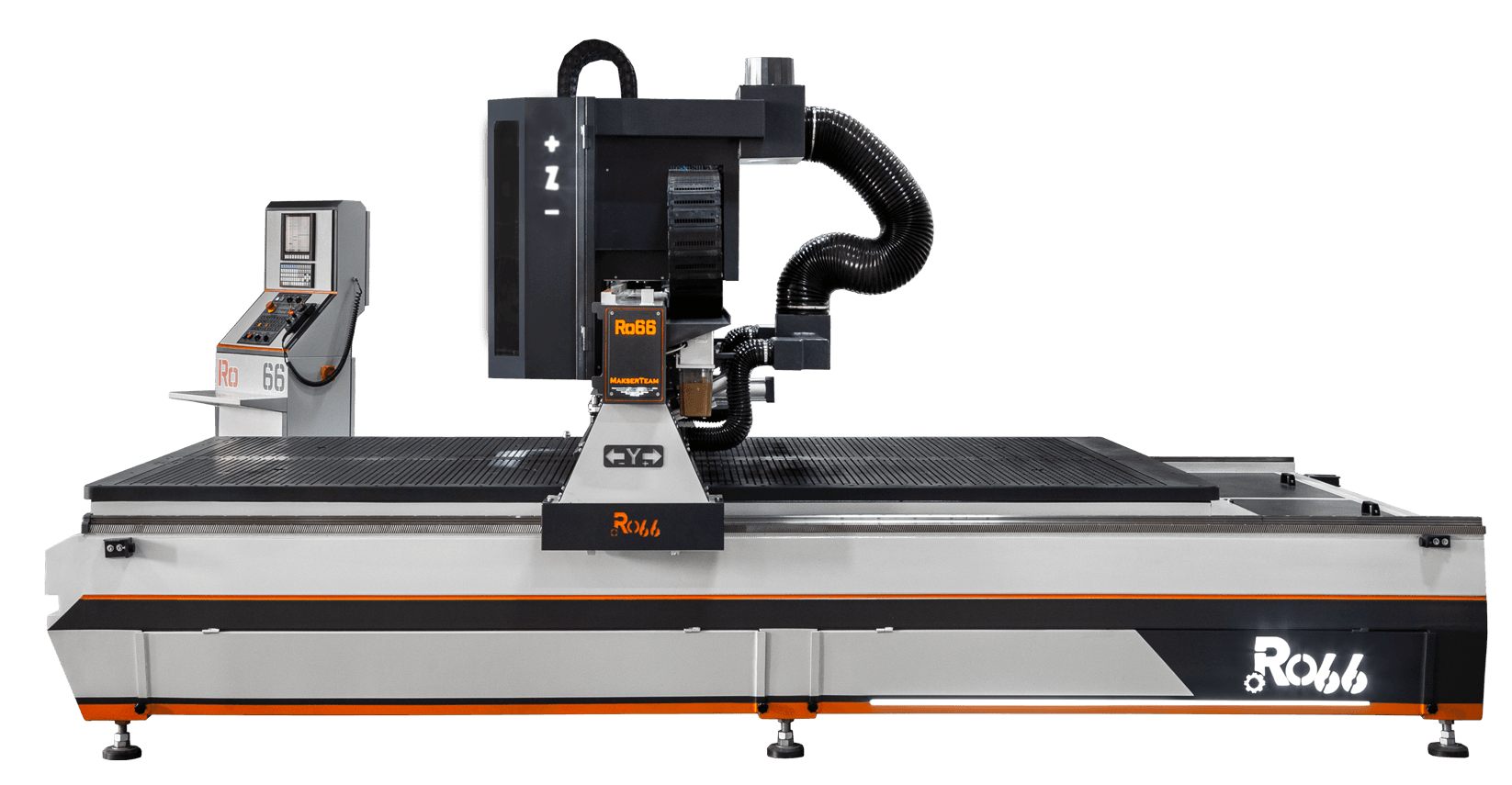

Delta Ro66 Series

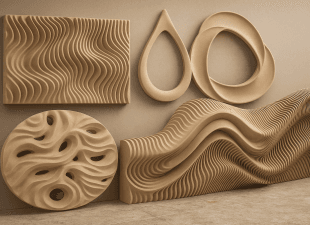

Ro66 - Touching The Soul Of Production

Behind every part there is real craftsmanship, and every line has a purpose.

Makser RO66 is a high-precision CNC woodworking router designed for industrial woodworking manufacturers.

Easy Control

With its advanced user interface and ergonomic panel design, it allows the operator to control the machine quickly, accurately and safely.

Automation-Supported System

Integrated structure with servo motors, automatic lubrication and tool measurement systems.

Industrial Durability

Reinforced steel body and motion systems covered by a 5-year warranty.

Long-Term Stability

Stable, high-quality cutting thanks to the direct transfer of loads to the machine frame.

High Performance

As the result of 20+ years of field experience, the RO66 CNC woodworking router sets a new standard in the industry.

Professional Results

High-precision cutting, vibration-free operation and maximum efficiency.

DELTA CONTROL UNIT

MAIN FEATURES

10.4” TFT Screen: Clear and intuitive user interface with a larger, high-resolution display

5-Axis Support: More freedom and versatility for complex workpieces

Enhanced Dust and Liquid Protection Panel: Higher durability in industrial environments

Programmable I/O Board with Unlimited Module Expansion: Wider signal management and advanced control

High-Speed EtherCAT Communication: Faster data transfer and synchronization

Next-Generation Handwheel Module: More precise adjustment and easier operation

Comprehensive Macro and Programming Support: More flexible and faster programming

Higher Processing Power and Speed: NC-511 handles even complex operations quickly and smoothly thanks to its powerful processor

Advanced Motion Control: High-precision interpolation and advanced servo synchronization for excellent machining quality

SERVO MOTORS & DRIVE

X AND Y AXIS SERVO MOTOR & DRIVE (DELTA)

For high-precision motion control of the X and Y axes on CNC machines, the Delta ECM-B3M-E21310-RS1 servo motor and ASD-B3-1021-F drive offer outstanding performance with 1.5 kW power and ETHERCAT communication protocol.

Thanks to the 20-bit incremental encoder, it provides vibration-free operation even at low speeds, while the 17-bit absolute encoder keeps position data safe even in case of power failure.

It delivers stable and fast axis movements in applications requiring high precision.

Z AXIS SERVO MOTOR (DELTA)

The Delta ECM-E21310-SS1 servo motor used on the Z axis provides both safety and precision in vertical movements with its 1.0 kW power and integrated holding brake.

In case of power failure, it prevents the Z axis from dropping and keeps the position fixed.

Thanks to the 20-bit incremental encoder and 17-bit absolute encoder support, high-resolution and reliable position control is achieved.

MAIN FEATURES (X–Y)

Servo Motor: DELTA ECM-B3M-E21310-RS1

Servo Drive: DELTA ASD-B3-1021-F

Power: 1.5 kW

Speed: 2000 / 3000 rpm

Operating Voltage: 220 VAC

Encoder: 20-bit incremental + 17-bit absolute

Communication: DCMNET

Application: X and Y axis motion control

Advantages: High positioning precision, low-speed stability, fast response

Z AXIS SERVO MOTOR (DELTA)

Servo Motor: DCL TA CCM-C21310-SS1

Power: 1.0 kW

Speed: 2000 / 3000 rpm

Operating Voltage: 220 VAC

Protection Class: IP65

Brake: Integrated holding brake

Encoder: 20-bit incremental + 17-bit absolute encoder support

Application: Z axis motion control

Advantages: Position holding, safe vertical movement, high precision

Spindle Ünitesi

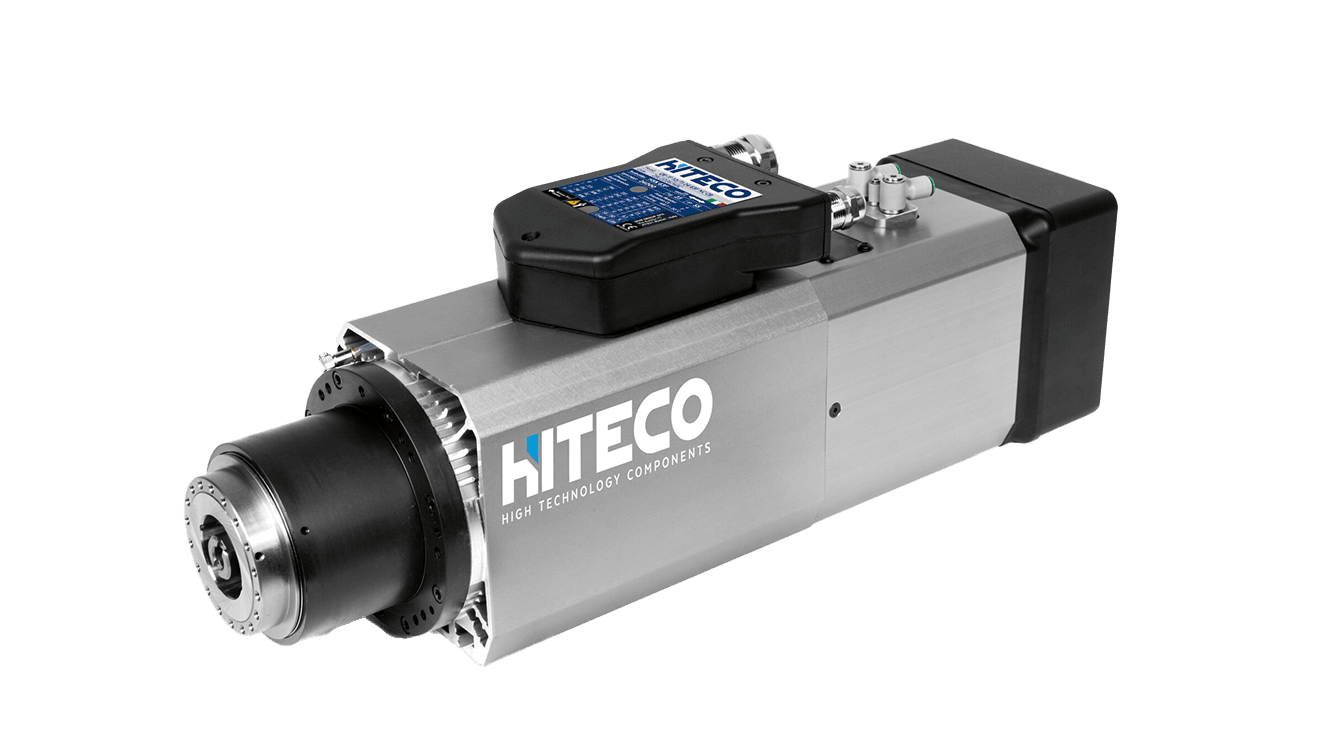

Spindle Unit– HITECO QE-1F

Power: 8.5 – 12 kW | Max Speed: 24,000 rpm

Cooling: 24V electro-fan (air-cooled)

Tool Holder: HSK 63F

SKF ceramic bearings, long-life grease lubrication

Smart sensor for temperature, speed and vibration monitoring

Supports drilling, flow drilling and tapping

Pneumatic double-acting tool change system

ADDITIONAL FEATURES

iM Smart Sensor: Real-time monitoring of speed, vibration and temperature

Maximum power output from 6000 rpm upwards

Easy and practical maintenance with periodic maintenance kits

Compatible with wood, aluminium, plastic and advanced materials

Supports drilling, flow drilling, threading and tapping operations

Optional encoder for ultra-high-precision machining applications

ADVANTAGES

High precision and superior performance

Flexible speed range

Durable and energy-efficient design

Wide range of applications

Automatic Systems & Smart Support

Automatic Lubrication System

- 2-litre HYRO OIL HD 46 compatible

- PLC-timed automatic lubrication cycles

- Balanced and precise lubrication of critical points

- No manual intervention needed, extends component life

Automatic Tool Changer

- Supports up to 16 tool positions

- Fully integrated with CNC commands

- Uninterrupted workflow, high production flexibility

- Reduces the need for manual intervention

Tool Length Measurement Probe

- High-precision automatic measurement

- Data transferred directly to the control unit

- Minimizes operator errors

- Shortens setup times

Automatic Unloading & Cleaning

- Part removal without operator intervention

- Speeds up the production process

- Provides part protection with precise placement

- Suitable for high-volume production

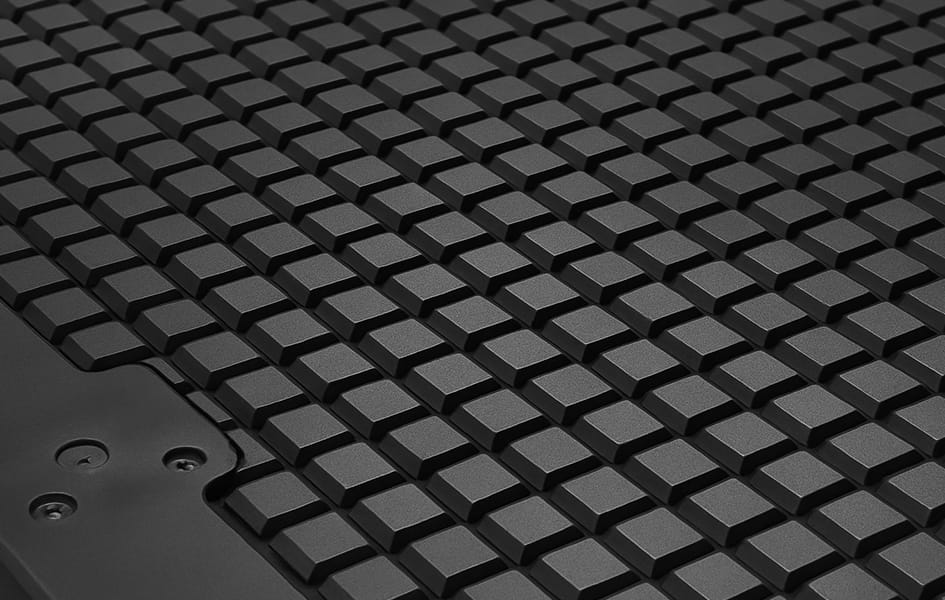

Vacuum System & Worktable

- 5-zone system with actuator-valve control

- 50 mm thick table with sealing support

- Strong holding power even for small parts

- High vacuum efficiency with closed-surface design

- Water-cooled vacuum pump

Automatic Positioning Pistons

- Guarantees material positioning with precise alignment

- Saves time and increases operator safety

- Adapts to different shapes and sizes

- Repeatable positioning for serial production

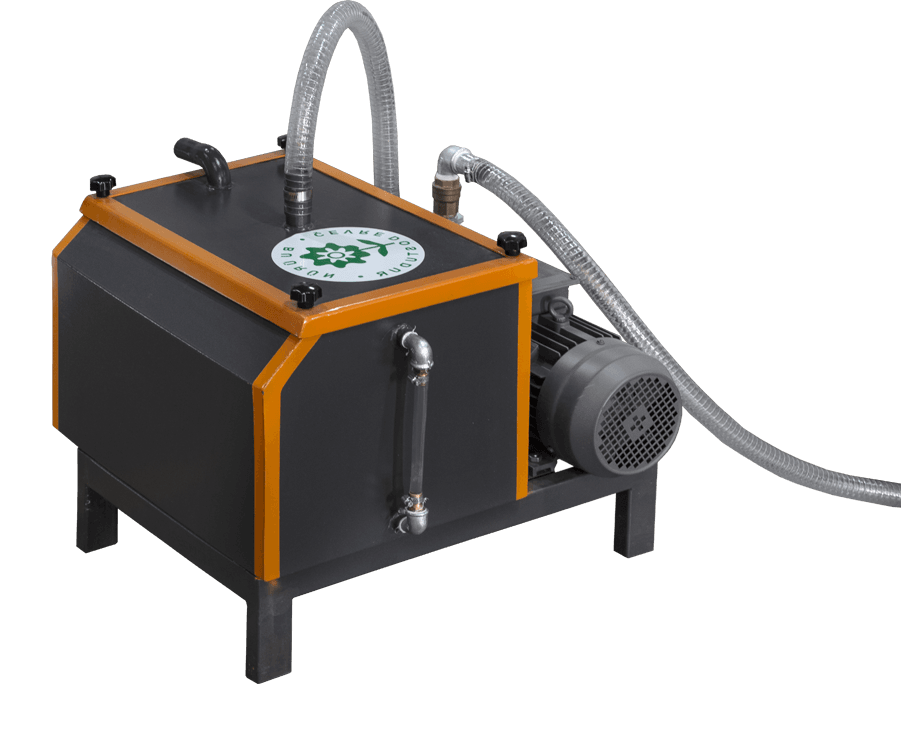

LIQUID-COOLED VACUUM PUMP

LIQUID-COOLED VACUUM PUMP

- Model / Type: Water-cooled liquid ring vacuum pump

- Power: 11 kW

- ank Capacity: 480 litres

- Liquid ring vacuum pumps operate by utilizing the physical properties of water.

While the water rotates inside the pump with centrifugal force, it creates vacuum. At the same time, water acts as a natural coolant and prevents the system from overheating.

- Liquid ring vacuum pumps operate by utilizing the physical properties of water.

ADVANTAGES

High Vacuum Power: Provides strong clamping of workpieces during machining, ensuring stability in precision operations

Heat Management: Natural cooling greatly reduces the risk of overheating

Low Noise Level: Provides a quieter and more comfortable working environment

Long Service Life and Reliability: Durable structure and effective cooling ensure a long service life

Energy Efficiency: Designed to reduce operating costs with low energy consumption

MAIN FEATURES

Environmentally friendly design

Low maintenance cost

Quiet operation

Long service life

Makser machines are equipped as standard with high-performance liquid-cooled vacuum pumps.

Depending on your needs, dry or oil-type vacuum motors are also available, providing maximum flexibility and efficiency in your production processes.

OPTIONAL FEATURES

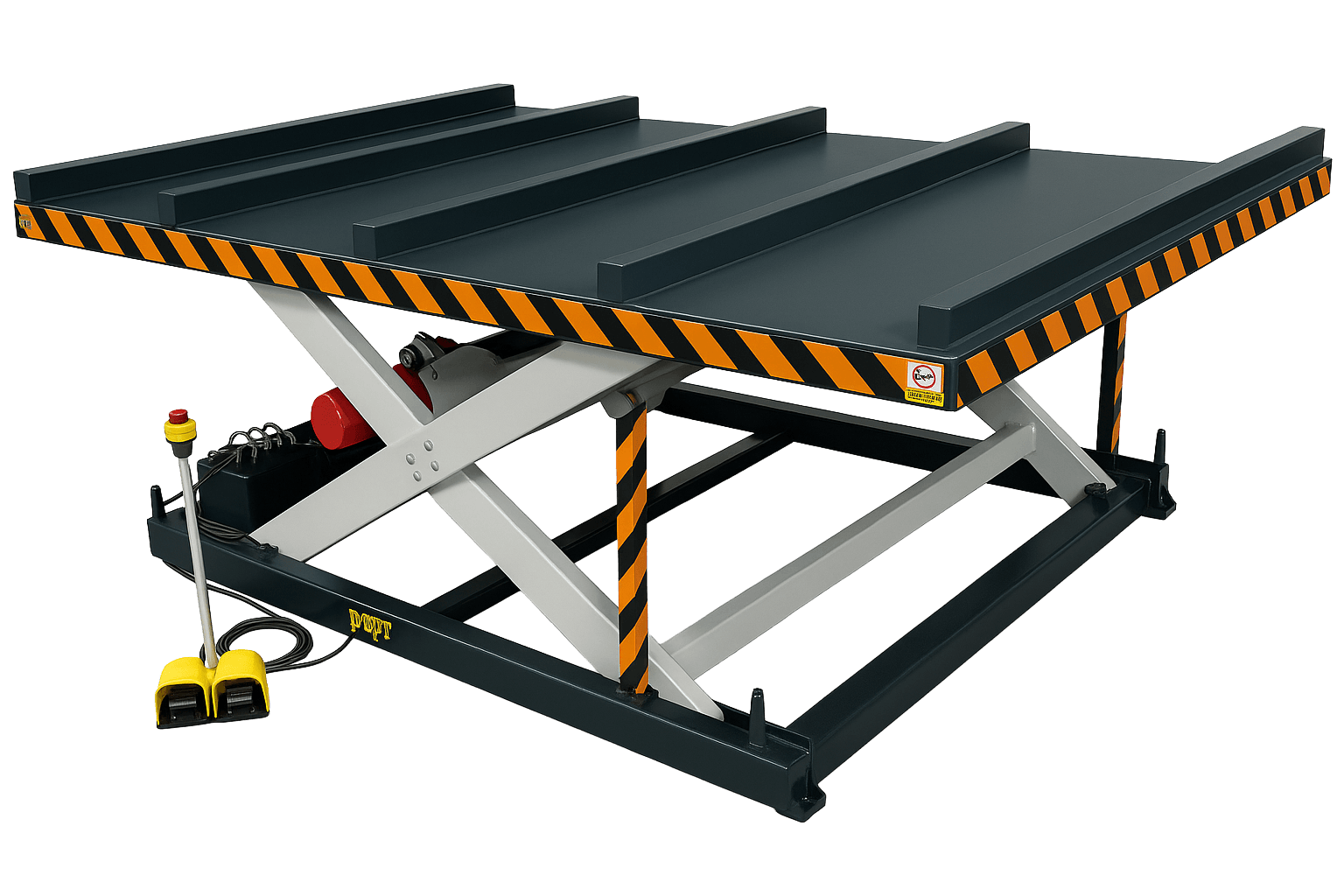

LOADING UNIT

- The automatic loading unit ensures fast and precise loading of workpieces onto the machine.

- The Makser Loading Unit minimizes operator intervention and significantly increases productivity.

ADVANTAGES

Continuous production with time savings.

Precise and repeatable part positioning.

Flexible design for different workpiece sizes.

Reduced labour requirement and lower operating costs.

Ideal solution for high-volume production environments.

Increased operator safety and ergonomic working conditions.

AUTOMATIC UNLOADING CONVEYOR UNIT

- The automatic conveyor unit ensures fast and safe unloading of machined parts from the machine.

- It supports continuous production flow, increases work safety and reduces labour costs.

ADVANTAGES

Continuous and uninterrupted production flow.

Safe transport that reduces the risk of accidents.

Time and energy savings compared to manual unloading.

Precise conveying system that protects product quality.

Ergonomic use and space-saving layout.

Flexible design compatible with different part sizes.

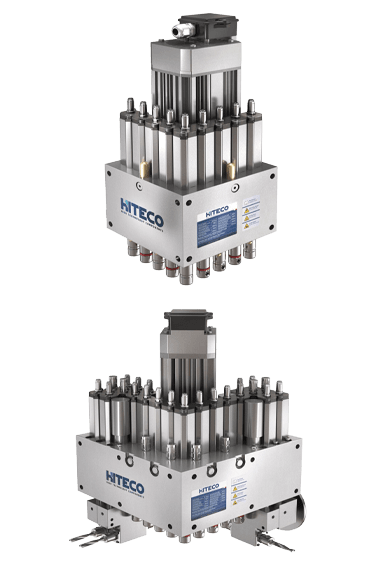

AGGREGATES AND BORING UNIT – HITECO

The aggregates and boring units in its product range increase the functionality of the machines, adding flexibility, speed and precision to production.

BORING GROUPS – FAST AND PRECISE DRILLING OPERATIONS

Optimized layout for multiple drilling operations.

Simultaneous processing on vertical and horizontal axes.

High-speed motor options.

Fully compatible structure with CNC control commands.

Repeatable high precision in mass production.

ADVANTAGES

Adds great versatility to CNC machines.

Reduces tool change time and increases production speed.

Automates complex operations and minimizes operator error.

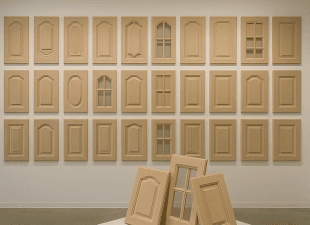

Can be integrated into various applications such as kitchen, bathroom, furniture and door production.

Robust, long-life design with low maintenance requirements.

ALPHACAM CORE + NESTING

From basic machining to simulation, CAD integration to reporting, it enables you to manage every step of your production processes with confidence.

With the Nesting module, ALPHACAM becomes not only a machining solution, but also a powerful tool for material optimization and scrap reduction.

It maximizes part yield from sheet, wood, plastic or composite panels, reducing production costs, speeding up processes and minimizing waste.

NESTING FEATURES

Smart nesting algorithms that minimize scrap

Comprehensive reporting for part traceability

Bridge nesting to save on tool travel time

Automatic detection and removal of common cuts

Reverse-side nesting

Full user control with manual nesting

Reduced tool changes for increased productivity

Offcut saving and remnant material management

Frequently Asked Questions (FAQ) – Makser RO66 CNC Woodworking Machine

In which applications can the RO66 Delta Series be used?

The RO66 Delta Series is used in production processes that require high precision, such as woodworking, door manufacturing, furniture production and panel cutting.

Which materials can it process?

It can work with high precision on a wide range of materials such as wood, MDF, chipboard, plastic, composite panels and aluminium.

What are the brands of the servo motors and control units?

In the RO66 Series, Delta and Siemens servo motors and control units are used.These systems offer high positioning accuracy, vibration-free operation at low speeds and position holding in case of power failure.

What are the spindle features?

The Hiteco QE-1F spindle unit offers:

8.5–12 kW power

24,000 rpm maximum speed

HSK 63F tool holder

Smart sensor for temperature, speed and vibration monitoring

Pneumatic double-acting automatic tool change system

What is the purpose of the vacuum table?

The vacuum system ensures that the workpieces are clamped firmly in place.

The 5-zone design provides stability and precision even for small parts.

How do the automatic systems make production easier?

Automatic lubrication system → reduces the need for manual maintenance

Automatic tool changer → enables uninterrupted production

Tool measurement probe → minimizes the margin of error

Automatic unloading conveyor unit → increases production speed

Is software support available?

Yes, its optinal. The RO66 Series is compatible with ALPHACAM Core + Nesting software.

It supports material optimization, scrap reduction, bridging and manual nesting features.

What is the warranty period?

All RO66 machines are covered by a 2-year warranty.

The motion systems, control unit, spindle and structural components are under warranty.

A 5-year warranty is provided for the reducer, rack and pinion and linear systems.

How does the technical support service work?

Instant support is provided via remote connection, along with spare parts supply, on-site technical team dispatch and software update/usage support.

Technical Specifications

This flexibility provides maximum efficiency and cost advantages for your production line.

| Özellİk | Değer |

|---|---|

| Working Area | 2100 mm x 3660 mm |

| Z Axis Travel | 200 mm |

| X Axis Speed | 70 m/dk |

| Y Axis Speed | 70 m/dk |

| Z Axis Speed | 30 m/dk |

| Spindle Power | 8.5 – 12 kW |

| Spindle Speed | 24.000 rpm |

| Tool Holder | HSK 63F |

| Vacuum Power | 11 kW /up to 605 m³ |

| Installed Power | 26.5 kW |

| Machine Weight | 4150 kg |

| Machine Dimensions | 2950 mm x 4900 mm x 2200 mm |

Warranty & After-Sales Support

Warranty Period

The motion systems, control unit, spindle and structural components are under warranty.

Installation & Training

Operator training, software usage and maintenance procedures are delivered hands-on.

Technical Support

Spare parts support, technical team deployment and software support are provided.