DoorFormer

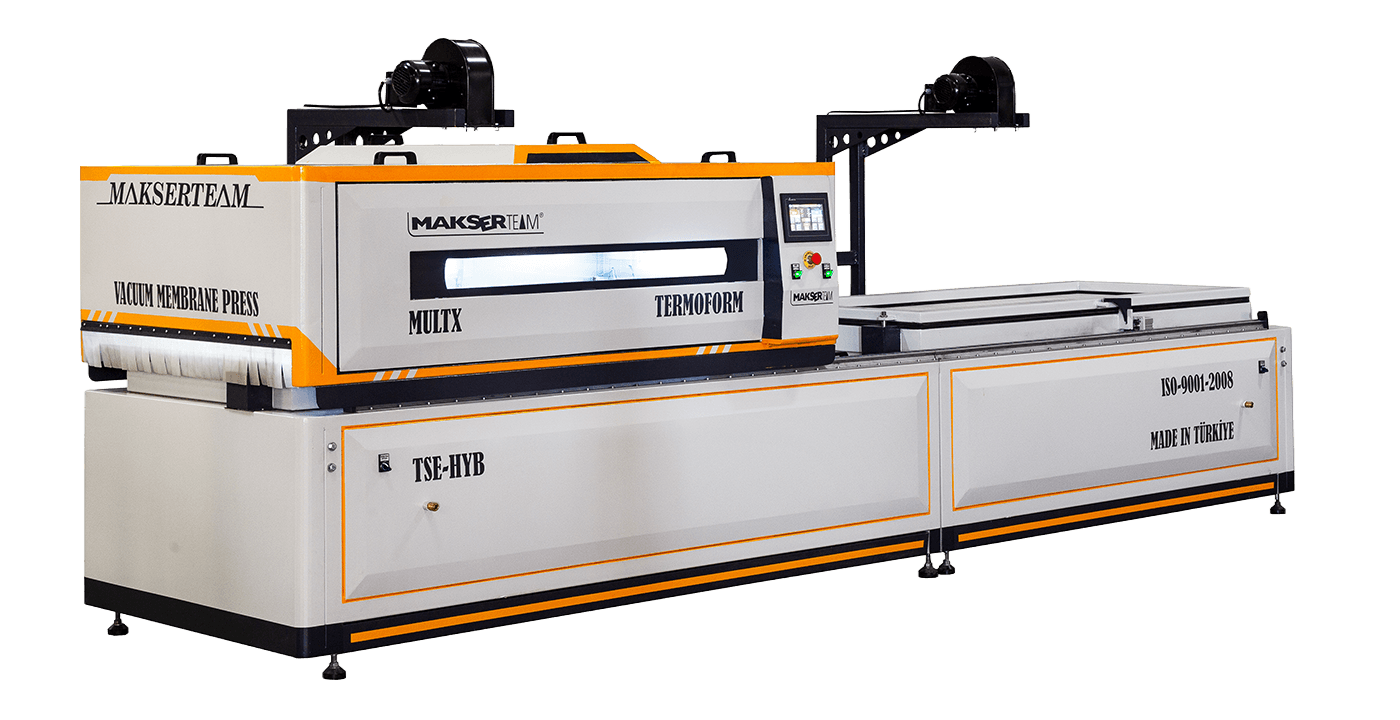

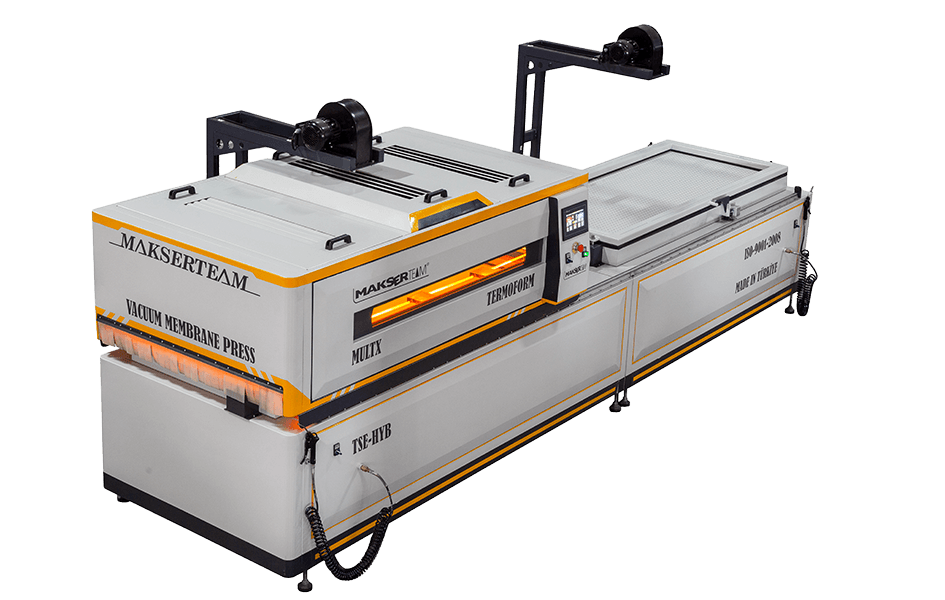

Makser DoorFormer is a next-generation door thermoforming machine designed for PVC, composite and ABS door panel production with perfect form accuracy.

Makser DoorFormer Thermoform Machine – PVC, Composite &

ABS Door Panel Forming Machine

The DoorFormer Thermoform Machine is a professional door panel forming machine that combines durability and aesthetics in door production. PVC, composite (e.g. WPC, PVC-based blends) and ABS panels placed on CNC-machined MDF molds are shaped using heat and vacuum technology to create flawless door surfaces.

A NEW STANDARD IN DOOR PRODUCTION • A NEW STANDARD IN DOOR PRODUCTION • A NEW STANDARD IN DOOR PRODUCTION •

A NEW STANDARD IN DOOR PRODUCTION • A NEW STANDARD IN DOOR PRODUCTION • A NEW STANDARD IN DOOR PRODUCTION •

A New Standard in Door Production

DoorFormer enables mass production of water- and impact-resistant, long-lasting and aesthetic doors. It provides speed, quality and flexibility for modern door manufacturers.

Powerful Performance with PVC, Composite & ABS Panels

PVC & Composite Panels (WPC, PVC-based blends): Typically used in the 1.5–3 mm thickness range. Ideal for water-resistant, lightweight and long-lasting door production. They are mostly available as foil-coated panels on the market and can be processed directly.

ABS and similar materials: Preferred especially for durable door surfaces thanks to their high impact resistance and low weight.

DoorFormer heats and softens these panels and presses them perfectly into the mold using vacuum technology; even the smallest details are reproduced flawlessly.

How Does the Production Process Work?

- The MDF mold prepared on a CNC is placed into the machine.

- The PVC, composite or ABS panel is placed on the mold.

- The heating system softens the panel.

- The vacuum system presses the material fully onto the mold.

- After cooling, the panel is ready to use as a front or back door surface.

Applications

- PVC doors

- Composite doors (WPC, PVC-based blends)

- ABS doors

- Decorative interior doors

- Water- and impact-resistant doors

With its advanced vacuum technology, the DoorFormer door thermoforming machine ensures precise shaping of every panel.

Advantages of DoorFormer

- Design Freedom:Any door design produced on a CNC mold can be applied.

- Efficiency: Mass production of front and back panels provides significant time and cost savings.

- Versatility: Optimized for 1.5–3 mm panels, yet also provides reliable results with thinner and thicker materials.

- Durability: Produces doors that are highly resistant to moisture, water and impacts.

This makes the DoorFormer not only a forming unit but a complete door thermoforming machine solution for modern manufacturing.

Why DoorFormer?

- Increases quality in door production.

- Reduces labour and production costs.

- Responds quickly to different customer requirements.

- Provides a competitive advantage in the global market.

As a high-efficiency door thermoforming machine, it supports consistent quality in large-scale production.