BLOG

MDF, PVC Foil Lamination & Adhesive Guide for High-Quality Furniture Production

High-Quality Furniture & Cabinet Door Production: MDF, PVC Foil Lamination and Adhesive Guide

High-quality furniture, cabinet doors, and interior room doors depend on the right combination of materials. The use of MDF, PVC foil lamination, and high-performance adhesive directly affects the durability, aesthetics, and long-term performance of the final product.

This SEO-friendly guide explains the key properties of MDF, the advantages of PVC foil coating, and why choosing the right adhesive is essential in furniture production.

What Is MDF? – Properties and Advantages

MDF (Medium Density Fibreboard) is produced by compressing fine wood fibres under high heat and pressure. Thanks to its homogeneous structure and smooth surface, MDF is an ideal base material for PVC foil lamination.

Key Features of MDF

Smooth and uniform surface suitable for coating

High durability and stability

Available in various thicknesses for different furniture designs

Widely used in furniture, cabinet doors, and interior panels

PVC Foil Lamination: Aesthetic, Protection & Versatility

✔ Broad color/texture range

Woodgrains, matte, glossy, soft-touch and solid colors.

✔ Strong durability

Resistant to moisture, scratches and daily wear; easy to clean.

✔ Process compatibility

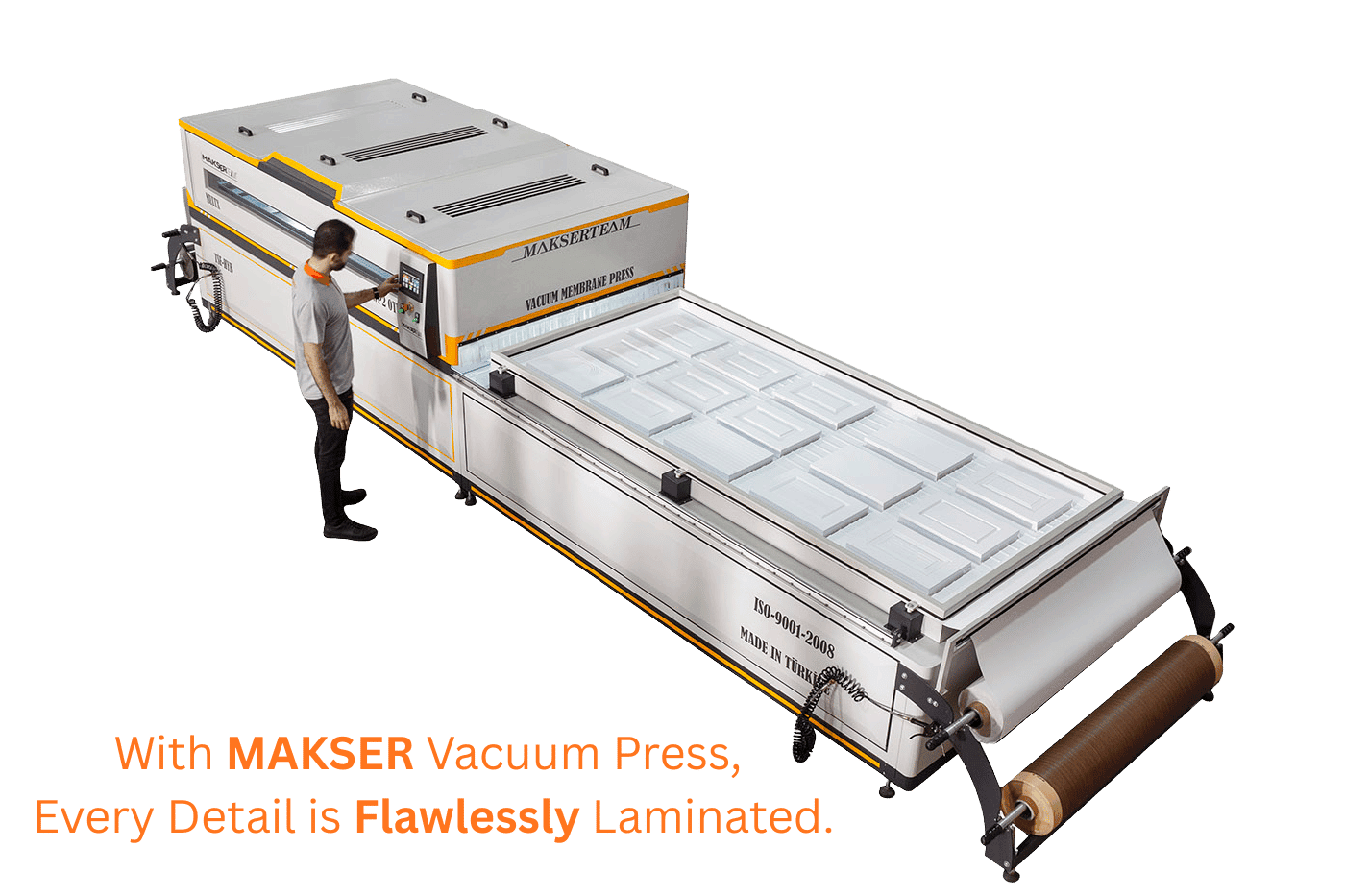

In a vacuum membrane press, controlled heat + strong vacuum ensures tight and uniform adhesion.

✔ Cost-effective

More economical than solid wood; ideal for scalable, repeatable production.

Adhesive Guide: Strong Bonding for Long-Term Performance

✔ Bonding strength

Use membrane-compatible, high-solid adhesives for a durable, long-lasting bond.

✔ Application

Spray gun for an even adhesive film.

If edge wrapping will be done, edges receive slightly heavier application.

✔ Flash-off time

Let panels rest for ≈30 minutes, depending on adhesive type.

✔ Critical note

Drying racks must be in a separate room from the spraying area.

Fresh adhesive vapor can land on resting parts and reduce bonding performance.

✔ Cleanliness

A dust-free surface is essential. Keep CNC cutting and pressing areas physically separated.

Process Flow: Clear and Simple

- CNC cutting & profiling — Door/panel sizing and model shaping

- Surface preparation — Light finishing sand if needed; dust removal

- Adhesive application & flash-off — Even film + separate drying area

- Vacuum membrane pressing — Correct heat curve + strong vacuum for flawless adhesion

- Trimming / final sizing — Remove excess foil; bring panel to final dimensions

- Edge banding (if preferred) — Clean edges with milling/scraping/polishing

- Hardware drilling — Handle, hinge, lock or functional holes

- Quality control & packaging — Surface, flatness and dimension checks; shipment prep

FAQ — Clear Answers

What PVC foil thickness should I use?

Varies by design. For cabinet doors, choose a thickness compatible with your production line for stable results.

Why must adhesive drying occur in a separate area?

Fresh adhesive vapor can settle onto panels and affect bonding quality.

Does vacuum level affect lamination?

Absolutely. Correct vacuum + proper temperature profile ensures tight adhesion in grooves, corners and deep profiles.

Makser Solutions for Consistent, High-Quality Production

- Makser RO66 CNC Router — Vibration-free body, precise profiling, clean cuts

- Makser Vacuum Membrane Press — Uniform foil lamination with repeatable quality

- Makser Cold Press — Even pressure for multilayer panel bonding

- Makser DoorFormer Thermoform Machine — Shaping PVC/WPC/ABS panels with heat & vacuum