BLOG

PVC Foil Coated Interior Doors | Production Workflow & Machinery Guide

PVC Foil Coated Interior Doors: Production Steps, Machines & Practical Notes

Producing a PVC foil coated interior door requires a clean, controlled workflow that delivers smooth surfaces, strong bonding and repeatable quality.

In this method, the door skin is shaped on a CNC router, only the face surface is coated with PVC foil using a vacuum membrane press, and the full body is assembled later with a cold press.

The finishing stage includes edge banding, lock–hinge drilling and final packaging.

This solution is widely chosen for housing projects and contractors due to its balanced cost, hygienic surface, and wide color/texture options.

Materials

Face panel (skin):

High-density MDF/HDF suitable for membrane pressing.

Most common thickness: 8 mm (industry range: 6–12 mm).

PVC foil thickness:

For interior doors, 0.16–0.20 mm foil is practical and economical.

Core material:

- EPS / XPS foam

- Kraft/honeycomb cardboard

- Other lightweight fillers depending on the project

Production Workflow

1) Cutting and Profiling — CNC Router

The face panel is cut to door size and profiled on a CNC router.

Makser RO66 CNC Router eliminates post-sanding when used with the correct cutting tools, thanks to its rigid body and vibration-free motion.

(For deep patterns, a light finishing sand may be applied.)

Siemens Cnc Router Woodworking Machinery

2) Adhesive Application & Flash-Off

Spray adhesive is applied evenly.

Since this method does not wrap the edges during vacuum pressing, the adhesive film focuses on the surface.

Important note:

Panels must not be dried in the same room where adhesive is sprayed.

Fresh adhesive vapor can resettle on the surface and cause defects.

Flash-off time: ~30 minutes, depending on adhesive type.

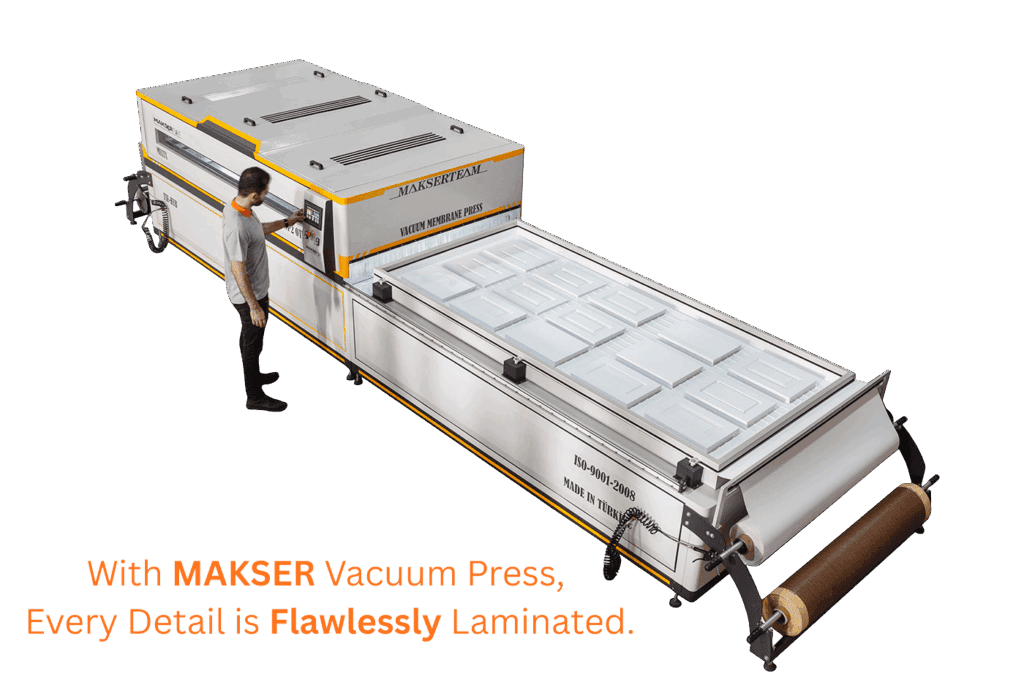

3) Vacuum Membrane Press — Surface Coating

The prepared skin is placed into the membrane press.

Only the face side is coated with PVC foil.

- No edge wrapping in this method

- Aim: a clean, smooth and defect-free film

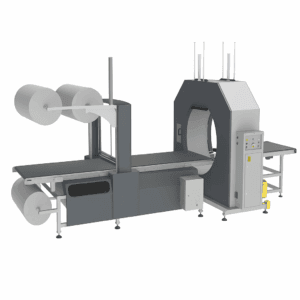

Makser Vacuum Membrane Press ensures stable results with controlled heating and strong vacuum.

Vacuum Pres / Vacuum Membrane Press

vacuum Membrane Press / Vacuum Press

Vacuum Press

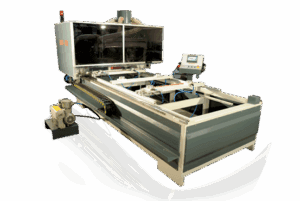

4) Body Assembly with Core — Cold Press

A cold press adhesive is applied to the inner (foil-free) surfaces of the front and back skins.

Core filler (EPS/XPS or kraft honeycomb) is placed inside, and the assembly is closed.

The set is pressed in a Makser Cold Press Machine for 0.5–8 hours depending on adhesive specifications.

Cold Pres

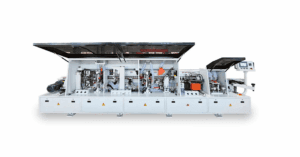

5) Final Sizing (Trim) → Edge Banding → Drilling

Final sizing / door trimming

Excess material is cut away and the door is brought to its final width and height.

PVC edge banding

Edges are banded with PVC tape through a complete finishing sequence:

banding → trimming → scraping → polishing

Drilling

Lock, handle and hinge locations are machined.

These can be opened either on the Makser RO66 CNC (with side unit) or on a Door Lock Drilling Machine for high-volume production.

6) Final Inspection & Packaging

Surface, edges, flatness and measurements are checked.

Doors are packaged with shrink/stretch material and prepared for shipment.

Frame & Casing Production — Profile Wrapping

Interior doors require matching frames and casings. You may:

Option 1 — Buy ready-made frames

Choose any color, model or specification from external suppliers.

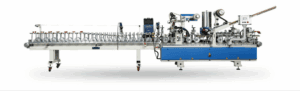

Option 2 — Produce in-house with profile wrapping

Purchase frames as raw profiles and coat them using a profile wrapping machine, ensuring perfect color/texture matching with the door.

Profile wrapping offers:

- High speed

- Consistent color

- Seamless integration with the door design

PVC Foil Width & Slitting (Waste Optimization)

Common foil widths: 1.20 m and 1.40 m

For 90 cm doors:

- 1.40 m rolls are slit into 1.00 m strips

- This reduces waste in the membrane press

- Remaining strips can be used in profile wrapping

A membrane press can be configured to 1.00 m table width for maximum efficiency.

Recommended Machine Park

- Makser RO66 CNC Router — cutting & profiling

- Makser Vacuum Membrane Press WP-2 — PVC surface lamination

- Glue Spreader (roller type) — controlled adhesive thickness

- Spray adhesive gun — uniform surface coating

- Makser Cold Press — body assembly

- PVC Edge Banding Machine — professional finishing

- Door Lock Drilling Machine — fast and standardized drilling

- 45/90° Frame Cutting Machine — accurate mitre cuts

- PVC Foil Slitting Machine — roll optimization

- Profile Wrapping Machine — frame/casing finishing

- Air compressor — dry and stable air supply

- Dust extraction & cleaning system — clean press/drying rooms

- Packaging machine — shrink/stretch wrapping

FAQ

What PVC thickness should I use for doors?

0.16–0.20 mm is ideal. Testing with your own line parameters is recommended.

Why must pressing/drying areas be separate from CNC?

Dust and adhesive vapor cause surface defects.

A clean, isolated press room is essential.

Why is only the surface coated in the membrane press?

This method focuses on a flawless top film.

Edges are closed later with PVC edge banding.

Should I drill on CNC or on a dedicated machine?

Both options work.

For high-volume production, a door lock drilling machine is faster and more consistent.

Should I buy frames ready-made or wrap them in-house?

Both methods are common.

Profile wrapping ensures perfect color match with the PVC foil coated interior door.

Conclusion

A PVC foil coated interior door offers an excellent balance of cost, aesthetics and durability—when produced with the right workflow and machines.

With Makser RO66 CNC, Makser Vacuum Membrane Press and Makser Cold Press, manufacturers achieve:

- Stable quality

- Repeatable results

- Efficient production

- Clean and durable surfaces

👉 Makser technology helps you build doors that stay beautiful for years.