BLOG

Achieving Excellence in Interior Door Manufacturing: The Role of Makser Machines

Why interior doors matter—and where Makser fits

Interior doors complete the look and function of a space. With Makser machines, manufacturers gain the precision, repeatability and uptime required to deliver PVC foil laminated interior doors that stay straight, look premium and last.

Design & material selection: a solid foundation

Successful production starts with the right materials and models. Makser systems work seamlessly with MDF, HDF, composite panels and PVC foils, giving manufacturers freedom in profiles, textures and colors while keeping processes stable and predictable.

Pvc Foils

CNC cutting & profiling — Makser precision

Your door’s form, lines and fit are defined here. Makser RO66 CNC Router ensures millimetric accuracy and clean edges so parts assemble fast and surfaces present flawlessly—both for flat panels and detailed profiles.

Cnc Woodworking Router

Cold pressing — structural strength

With Makser Cold Press machines, panels are consolidated under uniform pressure. The result is stable, robust door leaves with reduced risk of warping or telegraphing—an essential base for long-lasting surfaces.

Cold Pres Msp 20 OTM

Surface prep — smoothness before beauty

Clean, even surfaces are the bedrock of premium finishing. Makser solutions support controlled workflows that keep panels dust-free and consistent, so the final look is uniform from edge to edge.

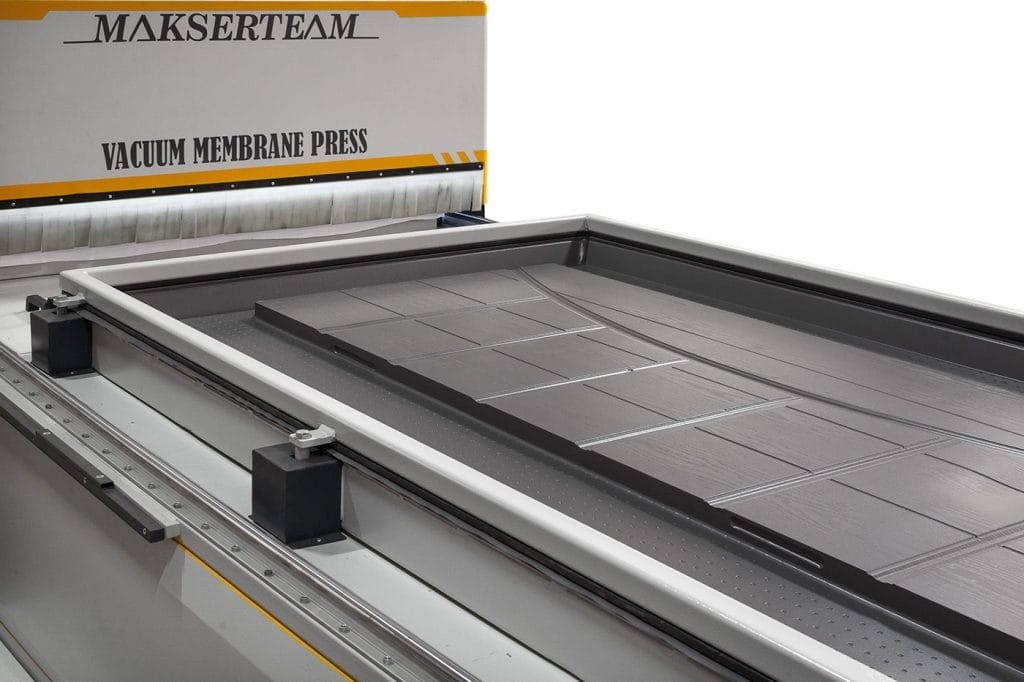

PVC foil lamination — aesthetics and protection

Makser Vacuum Membrane Press applies PVC foil to the door surface with controlled heat and strong vacuum. The outcome: PVC foil laminated interior doors with tight corner fit, consistent color, and a finish that resists moisture and everyday wear.

Vacuum Membrane Press Door – Vacuum Press

Thermoforming for composite & ABS panels

When projects call for shaped skins or impact-resistant faces, Makser DoorFormer Thermoforming systems form PVC, WPC (PVC-based composites) and ABS panels precisely:

- Effective for ≈1.5–3.0 mm panel thickness

- Water-resistant, impact-resistant faces

- Sharp detail in profiles and clean transitions

Interior Room`s Doors wpvc

Hardware fit & quality checks

Handles, locks and hinges are installed to spec. Every batch undergoes dimension, flatness and surface inspections so the doors reach site ready to hang—and to last.

Packing & delivery

Finished doors are protected, labeled and shipped with stable lead times. Makser’s balanced line design helps keep throughput steady from cutting to final wrap.

Where PVC foil laminated interior doors excel

- Residential & hospitality: easy-to-clean, design-rich surfaces

- Wet areas (bathroom, kitchen): moisture-resistant performance

- Commercial (office, school, healthcare): consistent finish and dependable durability

Advantages at a glance

- Durability & moisture resistance for everyday use

- Wide aesthetic range: woodgrains, matte, gloss, soft-touch

- Easy care: wipe-clean surfaces, stain resistance

- Process efficiency with repeatable heat/vacuum profiles and CNC accuracy

Makser machines across the line

- RO66 CNC Router — precise cutting and profiling for door components

- Cold Press — uniform pressure for structurally stable panels

- Vacuum Membrane Press — reliable PVC foil lamination with tight edge wrap

- DoorFormer Thermoforming — forming PVC/WPC/ABS door skins with detail fidelity

Let’s configure the right line for your parts, sizes and finishes. Request a demo or quotation.

FAQ (short)

Are PVC foil laminated interior doors suitable for wet areas?

When produced and installed correctly, yes—PVC foil surfaces perform well in bathrooms and kitchens.

How broad are the design options?

From classic woodgrains to matte, gloss and soft-touch solids, plus routed profiles and geometric lines.

What keeps results consistent?

Stable CNC tooling, controlled heat/vacuum profiles and proper pressing—areas where Makser machines excel.