BLOG

Underfloor Heating Insulation Panels | Foil Lamination with Makser Thermoform

Underfloor Heating Insulation Panels | Foil Lamination with Makser Thermoform

Foil lamination on EPS/XPS underfloor heating panels plays a critical role in protecting the insulation layer during screed pouring.

A properly laminated panel prevents screed leakage, protects the insulation structure and ensures stable thermal performance throughout the life of the floor system.

Makser Thermoform machines, designed with advanced heating zones and uniform vacuum/pressure distribution, combine high output, consistent bonding and reliable surface quality.

Why Apply Foil on Underfloor Heating Panels?

✔ Prevents screed penetration

Stops the liquid screed from entering the EPS/XPS core, extending the service life of the panel.

✔ Increases surface durability

Provides extra resistance against scratches, installation-related damage and mechanical stress.

✔ Produces cleaner, more consistent surfaces

Channels, pipe grooves and clip areas remain smooth and uniform.

✔ Maintains insulation value

Reduces capillary moisture absorption, keeping the thermal conductivity stable over time.

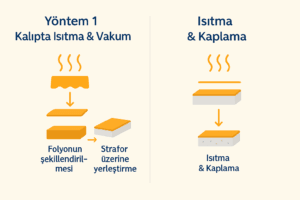

Two Practical Foil Lamination Methods

Makser Thermoform supports two main production methods, depending on geometry, throughput and cosmetic requirements.

1) Pre-Forming on the Mold + Later Lamination (Aluminum Mold Method)

In this method, an aluminum forming mold is placed on the machine table.

The foil is heated, shaped on the mold using vacuum/pressure, then removed and laminated onto the EPS/XPS panel.

Process Flow

Foil loading → Heating → Vacuum/forming → Removal → Lamination onto insulation panel → Cooling

Best for:

- Deep geometries

- High cosmetic expectations

- Thick or rigid foil structures

- Panels where shape stability is critical

Advantages

- Excellent geometric accuracy

- Smooth and consistent wall thickness on the formed foil

- Easy alignment and controlled quality

2) Direct In-Line Lamination on EPS/XPS (High-Speed Method)

EPS/XPS panels are fed into the thermoforming line.

Foil is heated, shaped and bonded directly on the panel in a single continuous process.

Process Flow

Panel feed → Foil loading → Preheating → Forming + bonding → Cooling → Cutting/stacking

Best for:

- High-volume production

- Medium-depth geometries

- Standard surface patterns

Advantages

- Fewer process steps → faster cycle times

- Lower operating costs

- Ideal for continuous production lines

Notes

- Very deep geometries may require extra control

- EPS density and surface hardness play a key role in bonding performance

Which Method Should You Choose?

| Criteria | 1) Pre-Forming on Mold | 2) Direct Lamination on EPS/XPS |

| Geometry depth | Best for deep or intricate shapes | Suitable for medium-depth |

| Production speed | Medium–High | High |

| Surface quality | Premium | Good–Very good |

| Process steps | One additional lamination step | Fewer steps |

| Tolerance sensitivity | More flexible | More sensitive to density & foil thickness |

Makser’s application team evaluates your foil type, production quantity and panel geometry to recommend the best combination for speed + quality + low waste.

Quality Control Checklist

- Bond test: Peel test to verify adhesion strength

- Surface uniformity: No orange-peel, waves or depressions

- Leak prevention: Screed/water simulation test

- Dimensional accuracy: Channel depth, width and cut tolerances

- Repeatability: Mold consistency across cycles

EPS vs XPS: Quick Reference

EPS (Expanded Polystyrene)

- Produced by steam-expanding polystyrene beads

- Lightweight and economical

- λ-value ≈ 0.030–0.040 W/m·K

- Slightly higher water absorption

- Common uses: external insulation, packaging, underfloor heating panels

XPS (Extruded Polystyrene)

- Produced by continuous extrusion

- Closed-cell structure

- Lower water absorption

- λ-value ≈ 0.028–0.035 W/m·K

- Ideal for high load areas, foundations, humid floors

Why Makser Thermoform?

Makser is known for industrial reliability across wood, composite and thermoforming machinery.

Our thermoforming systems offer:

- Precise heating zone control

- High forming speed

- Uniform bonding

- Stable quality in long production runs

Share your panel size, foil type and target throughput, and we’ll propose the most efficient configuration for your production line.

Frequently Asked Questions (FAQ)

Why is foil coating applied on underfloor heating insulation boards?

It prevents the screed from penetrating into the EPS/XPS, protects the panel, and keeps thermal performance stable.

Which method should I choose?

For deep and sensitive geometries, Pre-Forming in Mold is recommended.

Which types of foil are suitable?

PE/PP/PET or multi-layer laminations; the choice depends on the target durability and chemical/thermal requirements.

How can we increase production speed?

By balancing heating zones, stabilizing foil tension, and optimizing mold changeover times.

Contact us for pricing, demos and technical consultation.

👉 Makser Thermoform: Shaping quality, protecting performance.