BLOG

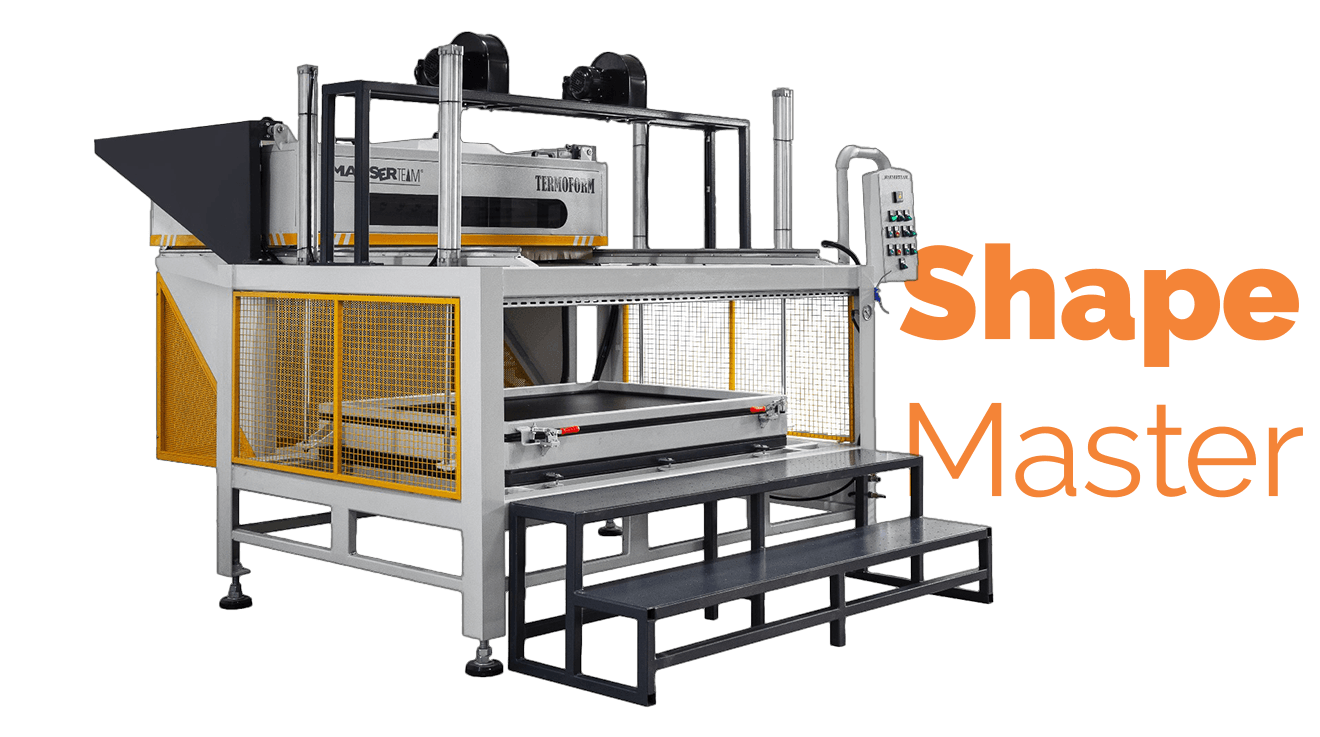

What Is Thermoforming? High-Quality Production with Makser Thermoform Machines

What is thermoforming?

Thermoforming is the process of heating a thermoplastic sheet until it softens and forming it over/into a mold using vacuum and/or pressure. Materials such as ABS, polystyrene (HIPS), polycarbonate and PVC take shape quickly and consistently when heat and vacuum profiles are controlled correctly—delivering parts that look premium and last.

Where it’s used

- Packaging: Lightweight, hygienic food and pharma trays

- Automotive: Interior/exterior trim, consoles, protective covers

- Medical: Device housings, protective shells

- Signage/Displays: 3D panels, illuminated signs, custom forms

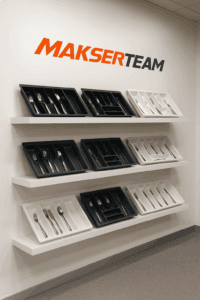

Makser Thermoform machines: built for consistent results

- Uniform heating: Multi-zone control for even sheet softening

- Strong vacuum: Tight detail capture and crisp edges

- Quick mold change: Short downtime, fast product switches

- Energy efficiency: Smart zone control and stable cycle times

- Recipe management: Save/recall parameters for repeat runs

From shallow trays to deep-draw shapes, Makser lines are designed to speed up setup and keep output stable.

Materials & typical thickness

- ABS: Impact-resistant faces and durable housings

- HIPS: Cost-effective trays and display items

- Polycarbonate: Heat-resistant, clear applications

- PVC: Decorative/functional panels (grade-dependent)

Tip: Choose thickness by draw ratio, detail depth and target surface quality; validate with short trials.

Thermoforming workflow (at a glance)

- Heat the sheet to the recipe profile

- Form it with vacuum/pressure over the mold

- Cool & release to stabilize geometry

- Trim & drill for final dimensions and features

- Inspect & pack for consistent delivery

Why Makser

- Repeatable quality via controlled heat/vacuum profiles

- Fast commissioning with recipe libraries and quick changeovers

- Flexible production for different sizes and geometries

- Lifecycle support: operator training, technical guidance, long-term service

FAQ (short)

Which plastics can I thermoform?

ABS, HIPS, polycarbonate, PVC and other thermoplastics suitable for sheet forming.

Does mold change slow us down?

Makser’s quick-change and recipe recall minimize downtime and keep quality consistent.

How do I keep edges clean?

Uniform heating, adequate vacuum and sufficient cooling preserve sharp detail and smooth edges.

Conclusion

Thermoforming brings design flexibility and production efficiency together. Makser Thermoform machines combine uniform heating, strong vacuum and quick mold change to deliver high-quality, repeatable results—project after project.

Let’s configure the right thermoforming line for your parts. Request a demo or quotation.